A device engineered to mitigate noise generated by fluid or gas movement through a system is under scrutiny. These devices typically employ internal baffling, sound-absorbing materials, or changes in cross-sectional area to reduce the amplitude of sound waves. An example is a component integrated into an exhaust system to decrease acoustic emissions from an internal combustion engine.

The incorporation of such technology yields several advantages. A primary benefit is a reduction in environmental noise pollution, contributing to improved community well-being. Historically, these devices have played a significant role in meeting regulatory standards for noise control across various industries, from automotive to manufacturing, ensuring compliance and minimizing acoustic impact.

The subsequent sections will delve into the specific designs, performance characteristics, and applications relevant to these acoustic dampening solutions, exploring how they are tailored to meet the unique demands of different engineering systems.

Practical Considerations for Acoustic Dampening Devices

Optimizing the functionality of fluid or gas noise reduction components requires careful consideration during selection, installation, and maintenance.

Tip 1: Material Selection: Choose materials based on the operating environment. Exhaust systems, for example, often necessitate stainless steel due to its resistance to corrosion and high temperatures, while other applications may allow for aluminum or specialized polymers.

Tip 2: Backpressure Management: Excessive backpressure can negatively impact system performance. Select a device that minimizes flow restriction while achieving the desired noise reduction, ensuring efficient operation.

Tip 3: Frequency Tuning: Noise is not uniform across all frequencies. Determine the dominant frequencies of the noise source and select a device designed to attenuate those specific frequencies effectively. Some are designed for low-frequency noise, while others target higher ranges.

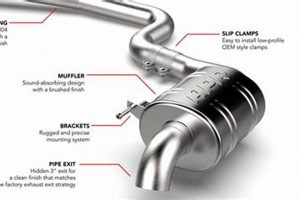

Tip 4: Installation Best Practices: Proper installation is critical. Ensure secure mounting to prevent vibration-induced noise and leaks, which can compromise performance and longevity. Follow manufacturer guidelines meticulously.

Tip 5: Regular Inspection and Maintenance: Periodic inspection can identify potential issues before they escalate. Check for corrosion, damage, or blockage, and address any concerns promptly to maintain optimal performance.

Tip 6: Sizing and Configuration: Correct sizing is paramount. Undersized components may be ineffective, while oversized units can be unnecessarily bulky and expensive. Consult with an acoustic specialist or the manufacturer to determine the appropriate size and configuration.

Effective application ensures noise reduction, operational efficiency, and long-term reliability. Prioritizing these considerations will optimize its effectiveness and contribute to a quieter and more efficient operational environment.

The concluding section will provide a summary of the key points discussed and highlight future trends and developments in acoustic dampening technology.

1. Noise Reduction

Noise reduction is the primary function of a flow muffler. These devices are engineered to attenuate sound waves generated by fluid or gas movement within a system, thereby minimizing acoustic emissions into the surrounding environment. Effective noise reduction is often a critical requirement for regulatory compliance and improving working conditions.

- Attenuation Mechanisms

A flow muffler achieves noise reduction through various mechanisms, including absorptive, reactive, and dissipative techniques. Absorptive mechanisms utilize sound-absorbing materials to convert acoustic energy into heat. Reactive designs employ chambers and tubes to reflect and cancel sound waves. Dissipative methods introduce controlled turbulence to dissipate sound energy. The optimal mechanism depends on the specific noise characteristics and system constraints.

- Frequency Specificity

The effectiveness of a device varies depending on the frequency of the noise. Some are designed to attenuate low-frequency noise, while others target higher frequencies. Industrial applications require a comprehensive noise assessment to identify the dominant frequencies and select a design accordingly. Automotive exhaust systems, for example, often incorporate resonators tuned to specific engine frequencies.

- Impact on System Performance

Noise reduction cannot be achieved without considering its potential impact on system performance. A poorly designed device can introduce excessive backpressure, reducing efficiency and increasing energy consumption. Therefore, selection requires balancing noise reduction with acceptable levels of flow restriction. Computational fluid dynamics (CFD) modeling is often employed to optimize designs for both acoustic performance and pressure drop.

- Material Properties and Durability

The materials used in the construction influence both noise reduction and longevity. Sound-absorbing materials must possess appropriate density and porosity characteristics. In harsh environments, corrosion-resistant materials are essential. Stainless steel is frequently used in exhaust systems due to its ability to withstand high temperatures and corrosive exhaust gases. Polymer-based materials may be suitable for less demanding applications.

The interplay between these facets is crucial for effective acoustic dampening. Selecting a device necessitates a thorough understanding of the noise source, the operating environment, and the desired level of noise reduction while minimizing adverse effects on system performance and ensuring long-term durability.

2. Backpressure

Backpressure, in the context of a fluid or gas handling system incorporating a noise reduction device, is the resistance to flow imposed by the device. The introduction of internal baffles, sound-absorbing materials, and changes in cross-sectional area, all common features in these units, inevitably generates a pressure increase upstream of the device. This increase can have a direct impact on the performance and efficiency of the entire system. For instance, in an internal combustion engine, excessive backpressure introduced by an improperly designed exhaust device can reduce engine power, increase fuel consumption, and potentially lead to premature engine wear. The cause is the restriction imposed on the exhaust gas flow, resulting in incomplete scavenging of combustion products and increased pumping losses. A properly selected device minimizes this resistance while still achieving the desired noise attenuation.

The importance of backpressure as a design parameter is underscored by the existence of “low backpressure” models tailored for applications where flow efficiency is paramount. Consider industrial ventilation systems where maintaining consistent airflow is essential for process control and employee safety. Introducing a device that excessively restricts airflow would compromise the system’s ability to remove contaminants effectively. Similarly, in high-performance engine applications, carefully engineered exhaust systems, incorporating devices with optimized internal designs, aim to strike a balance between noise reduction and minimizing exhaust restriction to maximize engine output. The use of computational fluid dynamics (CFD) simulations is increasingly common in the design process to accurately predict and optimize backpressure characteristics before physical prototypes are manufactured.

In summary, backpressure is an unavoidable consequence of incorporating a device designed to reduce noise in fluid or gas handling systems. The challenge lies in minimizing its detrimental effects on system performance. Understanding the relationship between design features, flow characteristics, and the resulting backpressure is critical for selecting a device that effectively addresses noise concerns without compromising overall system efficiency and reliability. Proper selection necessitates careful consideration of the specific application, operating conditions, and the potential trade-offs between acoustic performance and flow resistance.

3. Material Durability

Material durability is a critical determinant of the lifespan and sustained effectiveness of fluid or gas noise reduction devices. The operational environment dictates the specific demands placed on the materials used in construction, directly influencing the long-term performance and reliability of the component. In environments characterized by high temperatures, corrosive substances, or abrasive particles, inadequate material selection will inevitably lead to premature degradation, resulting in reduced noise attenuation capabilities, increased maintenance requirements, and ultimately, component failure. For example, in exhaust systems, where temperatures can exceed several hundred degrees Celsius and corrosive combustion byproducts are prevalent, the use of low-grade steel would result in rapid corrosion and structural weakening, thereby compromising its sound-dampening effectiveness. The direct consequence of compromised material integrity is a reduction in noise attenuation performance and the potential for catastrophic failure.

The selection of appropriate materials necessitates a thorough assessment of the operational parameters, including temperature ranges, chemical exposure, pressure fluctuations, and vibration levels. Stainless steel alloys, chosen for their inherent corrosion resistance and high-temperature strength, are frequently employed in demanding applications, such as exhaust systems and industrial process vents. Aluminum, prized for its lightweight properties and moderate corrosion resistance, may find use in less aggressive environments. Polymer-based materials, selected for their acoustic properties and chemical inertness, are also used in specific noise-dampening applications where temperature and mechanical stress are within acceptable limits. Furthermore, specialized coatings and surface treatments can augment material resistance to corrosion, abrasion, and thermal degradation. For instance, aluminized coatings are often applied to steel components in exhaust systems to enhance their resistance to oxidation at elevated temperatures.

In summary, material durability is not merely a desirable attribute, but a fundamental requirement for the effective and prolonged operation of fluid or gas noise reduction devices. Proper material selection, guided by a comprehensive understanding of the operational environment and potential degradation mechanisms, is essential to ensure sustained performance, minimize maintenance costs, and maximize the return on investment. The consequences of overlooking material durability can range from reduced noise attenuation to catastrophic component failure, underscoring the critical importance of this design consideration.

4. Frequency Tuning

Frequency tuning, in the context of fluid or gas noise reduction, refers to the deliberate design and optimization of a flow muffler to attenuate sound waves within specific frequency ranges. This approach is crucial because noise generated by fluid or gas movement is rarely uniform across the entire audible spectrum. Instead, dominant frequencies often characterize it, determined by factors such as flow rates, system geometry, and the presence of specific components. A device that effectively targets these dominant frequencies will provide significantly greater noise reduction than one designed for broadband attenuation.

- Resonance and Helmholtz Resonators

One common method of frequency tuning involves the use of Helmholtz resonators. These consist of a cavity connected to the main flow path via a narrow neck. The cavity resonates at a specific frequency determined by its volume and the dimensions of the neck. When sound waves at this resonant frequency enter the cavity, they are effectively trapped and dissipated, resulting in targeted noise reduction. Automotive exhaust systems frequently employ Helmholtz resonators to attenuate specific engine noise frequencies, improving the vehicle’s acoustic signature. The precise dimensions of the resonator must be carefully calculated to match the target frequency, necessitating accurate acoustic modeling and analysis.

- Reactive Muffler Design

Reactive mufflers utilize internal chambers and tubes to reflect and cancel sound waves. By carefully designing the dimensions and arrangement of these components, the muffler can be tuned to attenuate specific frequencies. For instance, a series of interconnected chambers can be designed to create destructive interference at a target frequency, effectively cancelling out that frequency. The effectiveness of reactive mufflers is highly dependent on the accuracy of the design and the precise dimensions of the internal components. Deviations from the design specifications can significantly degrade performance.

- Acoustic Modeling and Simulation

The design of frequency-tuned flow mufflers relies heavily on acoustic modeling and simulation techniques. Computational fluid dynamics (CFD) and finite element analysis (FEA) are used to predict the acoustic behavior of the muffler and optimize its design for specific frequency ranges. These simulations allow engineers to explore different design options and assess their impact on noise reduction performance before physical prototypes are built. This reduces the time and cost associated with the design process and enables the development of more effective and efficient devices. The accuracy of these simulations depends on the accuracy of the input parameters and the sophistication of the modeling techniques employed.

- Broadband vs. Narrowband Attenuation

While frequency tuning focuses on attenuating specific frequencies, some applications require broadband noise reduction. Broadband mufflers are designed to attenuate noise across a wider range of frequencies, although typically with lower overall attenuation compared to frequency-tuned devices. The choice between broadband and narrowband attenuation depends on the specific application and the characteristics of the noise source. In situations where the noise spectrum is broad and variable, a broadband muffler may be more appropriate. However, when the noise is dominated by specific frequencies, a frequency-tuned device will provide superior performance.

Frequency tuning is a critical aspect of flow muffler design, enabling the creation of devices that effectively target specific noise frequencies. The use of Helmholtz resonators, reactive muffler designs, and acoustic modeling techniques allows engineers to optimize mufflers for maximum noise reduction performance. The choice between broadband and narrowband attenuation depends on the specific application and the characteristics of the noise source. Understanding the principles of frequency tuning is essential for designing and selecting flow mufflers that meet the specific noise reduction requirements of a given system.

5. Installation Integrity

Installation integrity is paramount for the proper functioning and longevity of fluid or gas noise reduction devices. Improper installation compromises their acoustic performance, structural integrity, and system efficiency, negating the benefits of a well-designed component.

- Secure Mounting and Support

The physical mounting of a flow muffler must provide adequate support to withstand operational forces such as vibration, pressure fluctuations, and thermal expansion. Insufficient support can lead to stress fractures, leaks, and ultimately, complete failure. For example, a large industrial device installed without proper bracketing could experience excessive vibration-induced fatigue, leading to cracking at weld points and diminished acoustic performance. Secure mounting mitigates these risks.

- Proper Alignment and Sealing

Correct alignment and sealing are essential to prevent leaks and ensure optimal acoustic performance. Misaligned connections can create gaps that allow noise to escape, reducing the effectiveness of the device. Additionally, leaks can introduce unwanted pressure drops and compromise system efficiency. The use of appropriate gaskets and sealing compounds, correctly installed and tightened to specified torques, is crucial. Improper sealing can result in audible noise leaks and reduced overall system performance.

- Correct Orientation and Flow Direction

Many flow mufflers are designed to operate with a specific flow direction. Incorrect installation can significantly reduce their effectiveness or even damage the device. Markings on the device typically indicate the correct flow direction. Moreover, the orientation of the device may be critical to its acoustic performance. For example, a reactive muffler designed with internal chambers may only function correctly when installed in a specific orientation. Reversing flow direction could negate the design principles leading to inefficiencies.

- Compliance with Manufacturer Specifications

Adherence to the manufacturer’s installation instructions is crucial. These instructions provide specific guidance on mounting techniques, sealing procedures, and torque specifications. Deviating from these instructions can void warranties and compromise the device’s performance and safety. Failure to follow instructions may lead to premature failures or operational hazards.

Installation integrity is not merely a procedural formality but a critical element in ensuring the reliable and effective operation of a device. Paying meticulous attention to mounting, alignment, sealing, orientation, and manufacturer specifications ensures that the benefits of the device are fully realized and that the system operates efficiently and safely. Proper installation maximizes the lifespan and efficacy of the noise reduction equipment.

Frequently Asked Questions About flow muffler Technology

The following section addresses common inquiries regarding the application, functionality, and selection of fluid or gas noise reduction devices. This aims to provide clarity and insight into critical aspects of the technology.

Question 1: What constitutes a suitable material for flow muffler construction in corrosive environments?

The selection hinges upon the specific corrosive agents present and their concentrations. Stainless steel alloys, particularly those containing molybdenum, are frequently employed due to their enhanced resistance to chloride attack and other aggressive chemicals. Polymer-based materials may also be considered if they demonstrate compatibility with the chemical environment and can withstand the operating temperatures.

Question 2: How does backpressure influence the selection of a specific flow muffler design?

Excessive backpressure impedes system efficiency and potentially degrades performance. Therefore, devices offering minimal flow restriction while achieving the desired noise reduction are prioritized. This often involves designs that incorporate optimized internal geometries, larger cross-sectional areas, or specialized flow diffusion techniques to minimize pressure drop.

Question 3: What role does frequency tuning play in optimizing flow muffler performance?

Frequency tuning involves designing a device to specifically attenuate the dominant frequencies present in the noise spectrum. This approach allows for more targeted and effective noise reduction compared to broadband attenuation. Helmholtz resonators and reactive mufflers, designed to resonate at specific frequencies, are common examples of frequency-tuned devices.

Question 4: How critical is proper installation to the overall effectiveness of a flow muffler?

Installation integrity is paramount. Incorrect mounting, misaligned connections, or inadequate sealing compromises the device’s acoustic performance and potentially leads to premature failure. Adherence to the manufacturer’s instructions, including torque specifications and alignment procedures, is essential for optimal operation and longevity.

Question 5: Can a flow muffler be retrofitted into an existing system?

Retrofitting is possible, but requires careful consideration of several factors. The existing system’s flow characteristics, noise spectrum, and space constraints must be assessed. Selecting a device that is compatible with these parameters and can be physically integrated into the existing setup is crucial for successful retrofitting.

Question 6: How frequently should flow mufflers be inspected and maintained?

The inspection and maintenance frequency depends on the severity of the operating environment and the criticality of the application. In demanding environments, such as those involving high temperatures or corrosive substances, more frequent inspections are warranted. Periodic checks for corrosion, leaks, and structural damage are recommended to ensure continued performance and prevent costly failures.

The information provided in this FAQ section serves as a guide for understanding and addressing common concerns related to these devices. Consulting with acoustic specialists and manufacturers is recommended for specific applications and design considerations.

The following sections will explore future trends and advancements in acoustic dampening technology, highlighting emerging materials and innovative design approaches.

Conclusion

The preceding sections have explored various facets of fluid or gas noise reduction technology. Key considerations include material durability, frequency tuning, backpressure management, and installation integrity. Optimization across these parameters is essential for effective noise mitigation in diverse applications.

The future of acoustic dampening will likely see advancements in materials science, computational modeling, and active noise control techniques. Ongoing research and development are crucial to meet increasingly stringent noise regulations and improve the efficiency of industrial and commercial systems. Further exploration of these technologies is warranted to ensure quieter and more sustainable operational environments.

![Why Is Your Airpod Mic Muffled? [FIX] Now! Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Why Is Your Airpod Mic Muffled? [FIX] Now! | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-219-300x200.jpg)