Exhaust finishers, often constructed from stainless steel or chrome, are aftermarket accessories designed to enhance the aesthetic appearance of a vehicle’s exhaust system, particularly on heavy-duty, diesel-powered vehicles. These additions attach to the tailpipe, providing a customized look. As an example, a polished stainless-steel extension might be installed on a pickup truck to provide a cleaner, more finished visual compared to the stock exhaust outlet.

The incorporation of these accessories offers several advantages. Beyond visual appeal, they can provide a layer of protection against corrosion of the existing exhaust piping. Furthermore, some designs can subtly influence exhaust sound, deepening the tone without significantly increasing overall volume. Historically, these components were primarily cosmetic, but advancements have led to models designed to improve exhaust flow, though the performance gains are often minimal on unmodified vehicles.

The subsequent sections will detail the different types available, installation considerations, material choices, and relevant regulatory compliance factors that should be considered when selecting such an aftermarket product.

Selection Guidance

The following guidelines are intended to assist in the selection process, ensuring a suitable fit and optimal performance from aftermarket exhaust finishers for diesel vehicles.

Tip 1: Measure Exhaust Outlet Diameter: Accurately measure the outer diameter of the existing exhaust pipe. This measurement is critical to ensuring a proper fit. Select an accessory with an inlet diameter that corresponds directly with the exhaust pipe’s outer diameter. For example, if the existing pipe is 4 inches in diameter, choose a unit with a 4-inch inlet.

Tip 2: Material Selection for Longevity: Stainless steel offers superior corrosion resistance compared to aluminized steel or chrome-plated options, particularly in environments where road salt is prevalent. A stainless-steel product will generally provide a longer service life and maintain its appearance for a greater duration.

Tip 3: Consider the Angle and Length: Assess the desired aesthetic. Straight-cut designs offer a clean, simple look, while angled cuts can provide a more aggressive appearance. Also, consider the length of the accessory and its projection beyond the vehicle’s body; excessive projection may pose a hazard or be aesthetically unappealing.

Tip 4: Evaluate Clamping Mechanisms: The method of attachment is a key factor in long-term reliability. Stainless steel band clamps provide a secure and uniform clamping force, minimizing the risk of slippage or detachment. Avoid designs that rely solely on set screws, as these may loosen over time.

Tip 5: Verify Compatibility with Vehicle Configuration: Some vehicles have unique exhaust configurations or aftermarket modifications. Ensure that the selected accessory does not interfere with any existing components, such as suspension parts or trailer hitches. Clearance should be carefully assessed prior to purchase.

Tip 6: Sound Considerations: While primarily aesthetic, certain designs can alter the exhaust note. Resonated finishers may slightly dampen or smooth the exhaust sound, while non-resonated versions may amplify it. Consider the potential impact on sound levels and ensure compliance with local noise ordinances.

Tip 7: Professional Installation: If unsure about the installation process, professional installation is recommended. Incorrect installation can lead to exhaust leaks, detachment, or damage to the vehicle.

Adhering to these considerations can ensure proper fitment, durability, and overall satisfaction with an aftermarket exhaust enhancement.

These guidelines provide essential information for informed decision-making.

1. Aesthetics

The incorporation of aftermarket exhaust finishers significantly impacts the overall visual appeal of a diesel truck. These accessories, often fabricated from polished stainless steel or chrome, serve as a prominent visual element, enhancing the vehicle’s rear profile. The aesthetic upgrade ranges from subtle refinement to a more aggressive, customized appearance, influencing the perceived quality and style of the vehicle. For example, a black ceramic-coated tip can complement a truck with dark accents, while a highly polished stainless-steel tip might accentuate a vehicle with brightwork detailing.

The design of the exhaust finisher, including its shape, size, and finish, contributes directly to the vehicle’s perceived image. Angled cuts project a sportier demeanor, whereas straight cuts convey a sense of understated elegance. The diameter and length of the finisher, relative to the truck’s proportions, further refine the aesthetic impact. An oversized or poorly fitted accessory can detract from the vehicle’s appearance, while a well-chosen and properly installed finisher seamlessly integrates with the overall design. The selection of a specific design reflects the owner’s individual preferences and their desired statement.

Ultimately, the aesthetic contribution of an exhaust finisher for a diesel truck extends beyond mere decoration. It represents a deliberate enhancement of the vehicle’s visual identity, communicating attention to detail and a personalized touch. The choice of material, finish, and design elements are crucial considerations in achieving a harmonious and impactful aesthetic outcome.

2. Corrosion Resistance

Corrosion resistance is a critical attribute of exhaust finishers for diesel trucks, primarily due to the harsh operating environment these vehicles endure. Diesel exhaust contains corrosive byproducts, including sulfur compounds and water vapor, which, when combined, form acids that attack metallic surfaces. Furthermore, diesel trucks often operate in regions where road salt is used extensively during winter, exacerbating corrosion through electrochemical reactions. Consequently, the longevity and aesthetic appeal of an exhaust finisher are directly determined by its ability to withstand these corrosive elements. For example, an exhaust finisher constructed from low-grade steel will rapidly exhibit rust, pitting, and eventual structural failure, while a stainless-steel unit will maintain its integrity and appearance for a significantly longer period.

The practical significance of understanding corrosion resistance lies in the long-term cost savings and reduced maintenance associated with using corrosion-resistant materials. Although stainless steel or ceramic-coated finishers may have a higher initial cost than chrome-plated or aluminized steel alternatives, their extended lifespan translates to lower replacement costs over the vehicle’s operational life. Moreover, a corroded exhaust finisher can detract from the truck’s appearance, negatively impacting its resale value. Selecting a material with inherent corrosion resistance, such as 304 stainless steel, is therefore a prudent investment. The application of protective coatings, such as ceramic coatings, provides an additional barrier against corrosion, further extending the service life of the exhaust finisher.

In summary, the connection between corrosion resistance and diesel truck exhaust finishers is fundamentally one of durability and long-term value. The selection of materials and coatings with high corrosion resistance is essential for maintaining the aesthetic appeal, structural integrity, and overall lifespan of these accessories. Challenges remain in balancing material cost with corrosion performance, but the long-term benefits of corrosion resistance far outweigh the initial investment. This understanding aligns with the broader theme of maximizing vehicle performance and minimizing maintenance requirements in demanding operating conditions.

3. Sound Modification

Exhaust finishers, while primarily aesthetic, can influence the perceived sound characteristics of a diesel truck. This effect stems from alterations to the exhaust gas flow path and the resonating properties of the tailpipe. The degree of sound modification varies depending on the finisher’s design, internal structure, and material composition. For example, a larger diameter finisher may produce a slightly deeper exhaust note due to the increased volume available for sound wave propagation. Similarly, a resonated finisher, incorporating internal chambers, can attenuate certain frequencies, resulting in a smoother, less harsh sound profile. The importance of sound modification lies in its ability to subtly customize the vehicle’s aural signature without requiring extensive exhaust system modifications.

The practical application of this understanding is evident in aftermarket preferences. Some owners seek to enhance the throaty rumble associated with diesel engines, opting for finishers designed to amplify lower frequencies. Conversely, others prioritize noise reduction, particularly in urban environments or residential areas. In such cases, resonated finishers or those with sound-dampening materials are selected. The impact on sound levels is particularly noticeable during acceleration and deceleration. The effect is often subtle but can contribute significantly to the overall driving experience. Furthermore, the material of the finisher can affect sound characteristics; stainless steel may produce a brighter tone compared to aluminized steel.

In summary, the connection between exhaust finishers and sound modification is subtle yet discernible. The design and material choices of the finisher can alter the exhaust note, influencing the vehicle’s auditory profile. However, it is crucial to consider local noise regulations and personal preferences when selecting a finisher with sound-modifying characteristics. The challenges lie in achieving the desired sound effect without compromising performance or violating legal limitations. The impact contributes to the broader topic of vehicle personalization, reflecting the owner’s preferences and potentially enhancing their driving experience.

4. Diameter Compatibility

Diameter compatibility is a fundamental consideration when selecting exhaust finishers for diesel trucks. This refers to the precise matching of the finisher’s inlet diameter to the outer diameter of the existing exhaust pipe. Failure to achieve accurate diameter compatibility results in either an inability to install the accessory or a compromised connection that is prone to leaks and detachment, therefore it is crucial to ensure accuracy in diameter.

- Precise Measurement

Accurate measurement of the existing exhaust pipe’s outer diameter is the initial step. Calipers or a measuring tape should be used to determine the exact dimension. This measurement serves as the basis for selecting an exhaust finisher with a matching inlet diameter. For example, if the exhaust pipe measures 4 inches, a finisher with a 4-inch inlet is required. Disregarding this step can lead to purchasing an incompatible accessory.

- Inlet Design Variation

Exhaust finishers are designed with varying inlet configurations, including slip-fit and weld-on types. Slip-fit designs require a precise diameter match to ensure a secure connection utilizing clamps. Weld-on types may allow for slight diameter adjustments through cutting and welding, but a close initial match simplifies the installation process and maintains exhaust system integrity. Ignoring these differences can result in improper sealing and exhaust leaks, ultimately affecting emissions and performance.

- Adapter Use Considerations

While adapters or reducing sleeves can be used to accommodate slight diameter discrepancies, their application introduces potential points of failure. Adapters can create turbulence in the exhaust flow, and the additional connections increase the risk of leaks. These compromises should only be considered when a direct diameter match is unavailable. If adapters are used, high-quality components and secure clamping mechanisms are essential to minimize potential issues.

- Impact on Exhaust Flow

Improper diameter compatibility can negatively affect exhaust flow. A finisher with a significantly smaller inlet diameter than the exhaust pipe creates a restriction, increasing backpressure and potentially reducing engine performance. Conversely, an excessively large inlet diameter can create turbulence, disrupting smooth exhaust flow. Maintaining a consistent diameter throughout the exhaust system is crucial for optimal performance and efficiency.

Achieving accurate diameter compatibility is paramount for the proper installation and function of exhaust finishers on diesel trucks. Failure to adhere to this principle can result in installation difficulties, exhaust leaks, reduced performance, and potential damage to the exhaust system. Attention to detail and precise measurements are essential to ensure a secure and efficient connection.

5. Material Durability

Material durability is a paramount attribute in the context of exhaust finishers for diesel trucks. The operational environment exposes these accessories to extreme temperatures, corrosive compounds, and physical stresses, demanding robust material properties to ensure longevity and maintain aesthetic appeal. Inferior materials degrade rapidly, necessitating frequent replacements and undermining the intended visual enhancement.

- Stainless Steel Grade Selection

The choice of stainless steel grade significantly impacts durability. 304 stainless steel offers adequate corrosion resistance for many environments, while 316 stainless steel provides enhanced protection against chlorides and road salts. The selection hinges on regional climate and road maintenance practices. Improper grade selection can lead to premature rusting and structural failure. For example, a truck operating in coastal regions requires 316 stainless steel to withstand saltwater exposure.

- Coating Application and Integrity

Protective coatings, such as ceramic coatings or high-temperature paints, enhance the durability of exhaust finishers. These coatings act as barriers against corrosion, heat oxidation, and physical abrasion. The integrity of the coating is crucial; chipping, cracking, or peeling compromises its protective function, exposing the underlying material to degradation. Regular inspection and maintenance of coatings are necessary to maximize their effectiveness. For instance, a ceramic coating can withstand temperatures up to 1200F, preventing discoloration and corrosion under extreme exhaust heat.

- Weld Quality and Joint Strength

The quality of welds joining different components of the exhaust finisher directly affects its structural integrity. Poorly executed welds are prone to cracking under thermal stress and vibration, leading to exhaust leaks and eventual failure. Properly executed welds using appropriate techniques and filler materials ensure robust joints capable of withstanding demanding operating conditions. An example of robust construction includes TIG welding, which offers precise control and high-strength joints.

- Thickness and Gauge of Material

The thickness or gauge of the material used in the exhaust finisher’s construction influences its resistance to physical damage and corrosion. Thicker materials offer greater resistance to denting, bending, and perforation from road debris. They also provide a greater barrier against corrosion, extending the component’s lifespan. Selecting an appropriate gauge material based on the vehicle’s operating conditions is essential for ensuring long-term durability. For instance, heavy-duty trucks operating on unpaved roads require thicker gauge exhaust finishers to withstand potential impacts.

These facets collectively highlight the importance of material durability in the context of exhaust finishers for diesel trucks. The selection of appropriate materials, coatings, weld quality, and material thickness directly influences the accessory’s longevity, aesthetic appeal, and overall value. Ignoring these considerations results in reduced lifespan, increased maintenance costs, and compromised vehicle appearance.

6. Installation Security

Installation security directly impacts the longevity, functionality, and safety of exhaust finishers on diesel trucks. A properly secured accessory ensures a reliable connection to the exhaust system, preventing detachment, leaks, and potential damage to the vehicle or surrounding environment. Conversely, inadequate installation poses risks ranging from minor aesthetic inconveniences to serious safety hazards.

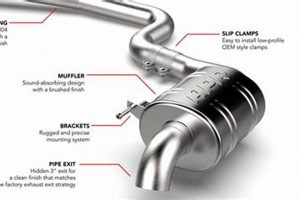

- Clamping Mechanism Effectiveness

The clamping mechanism is a critical component of installation security. Stainless steel band clamps, U-bolts, and specialized locking devices are common methods for securing exhaust finishers. The chosen mechanism must provide sufficient clamping force to maintain a secure connection under the stresses of vibration, thermal expansion, and road impacts. For example, a band clamp constructed from high-grade stainless steel and properly torqued provides a uniform clamping force, minimizing the risk of slippage. Inadequate clamping force or the use of inferior materials can lead to detachment, particularly in demanding operating conditions.

- Weld Integrity and Penetration

In weld-on installations, the integrity and penetration of the weld are paramount. A properly executed weld fuses the exhaust finisher to the existing exhaust pipe, creating a permanent and robust connection. Insufficient weld penetration or the presence of porosity weakens the joint, making it susceptible to cracking and failure under stress. Certified welders using appropriate welding techniques and filler materials ensure weld integrity and long-term durability. Non-professional welding may result in an unstable connection.

- Proper Alignment and Fitment

Ensuring proper alignment and fitment is essential for installation security. Misalignment can create stress points within the exhaust system, increasing the risk of leaks and detachment. The exhaust finisher must be properly aligned with the exhaust pipe to ensure a uniform clamping force or a secure weld joint. For instance, if the finisher is angled improperly, it can place undue stress on the connection point, eventually leading to failure. Accurate measurements and careful attention to detail are critical for achieving proper alignment and fitment.

- Regular Inspection and Maintenance

Even with a secure initial installation, regular inspection and maintenance are necessary to ensure ongoing security. Visual inspections should be conducted periodically to check for signs of loosening, corrosion, or damage to the clamping mechanism or weld joint. Retightening clamps or repairing damaged welds prevents minor issues from escalating into major problems. Proactive maintenance extends the lifespan of the exhaust finisher and maintains the integrity of the exhaust system. For example, annual inspections and re-torqueing of clamps can prevent loosening due to thermal cycling and vibration.

These facets underscore the multifaceted nature of installation security in the context of exhaust finishers for diesel trucks. A combination of robust clamping mechanisms, proper welding techniques, accurate alignment, and regular maintenance is essential for ensuring a secure and reliable connection. Neglecting these aspects compromises the functionality, safety, and longevity of the exhaust finisher, potentially leading to costly repairs and safety hazards.

7. Regulatory Compliance

Regulatory compliance is a significant consideration when selecting and installing exhaust finishers on diesel trucks. These accessories, while primarily cosmetic, must adhere to established noise level restrictions, emissions standards, and safety regulations to ensure legal operation. Failure to comply with relevant regulations can result in fines, vehicle impoundment, or mandatory removal of the non-compliant component. Thus, an understanding of these regulations is essential.

- Noise Emission Standards

Many jurisdictions enforce noise emission standards for motor vehicles, including diesel trucks. Exhaust finishers that significantly increase exhaust noise levels can violate these standards. Regulations typically specify maximum permissible decibel levels at various engine speeds. Aftermarket accessories must not cause the vehicle to exceed these limits. Enforcement often involves roadside noise level testing. Select finishers designed to maintain noise levels within legal limits.

- Emissions Control Device Tampering

Federal and state regulations prohibit tampering with emissions control devices. Exhaust finishers must not interfere with the proper functioning of catalytic converters, diesel particulate filters (DPFs), or other emissions control components. Altering or removing these devices is illegal and can result in substantial fines. Certain designs may inadvertently affect backpressure or exhaust gas flow, potentially impacting emissions control system performance. Ensure the selected finisher is compatible with the vehicle’s emissions control system and does not impede its operation. Seek certification or documentation from the manufacturer confirming compliance with emissions regulations.

- Safety Standards and Projections

Safety standards dictate the permissible projection of vehicle components beyond the vehicle’s body. Exhaust finishers must not extend excessively, posing a risk to pedestrians or other vehicles. Sharp edges or protruding elements are also prohibited. Regulations often specify maximum allowable lengths and clearances. Compliance with these standards ensures the accessory does not create a safety hazard. Verify the finisher’s dimensions and design meet applicable safety requirements.

- State and Local Variations

Regulations governing exhaust systems and related accessories can vary significantly between states and even local jurisdictions. Some areas may have stricter noise level limits or specific requirements for exhaust system modifications. It is crucial to research and comply with the regulations applicable to the vehicle’s area of operation. Consult local authorities or relevant government agencies to determine specific requirements. Ignoring local variations can lead to enforcement actions, even if the accessory is compliant in other regions.

These considerations collectively underscore the importance of regulatory compliance when integrating exhaust finishers with diesel trucks. Adherence to noise emission standards, emissions control device regulations, safety standards, and local variations is essential for legal operation and responsible vehicle modification. Diligence in researching and complying with applicable regulations prevents potential legal repercussions and contributes to environmental responsibility.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust finishers for diesel trucks, offering guidance based on technical considerations and practical applications.

Question 1: Do exhaust finishers improve diesel truck performance?

Generally, performance gains from exhaust finishers alone are minimal on unmodified diesel trucks. While some designs may subtly influence exhaust flow, the primary benefit is aesthetic enhancement rather than significant horsepower or torque improvements.

Question 2: What is the expected lifespan of a stainless-steel exhaust finisher?

The lifespan of a stainless-steel exhaust finisher depends on the grade of stainless steel used and the environmental conditions. A high-quality 304 or 316 stainless-steel finisher can last for several years, even in harsh climates, with proper maintenance and cleaning.

Question 3: Are all exhaust finishers compatible with every diesel truck model?

No, compatibility depends on the exhaust pipe diameter and configuration. Accurate measurement of the existing exhaust outlet is crucial for selecting a compatible finisher. Some modifications may be required for non-standard exhaust systems.

Question 4: Do exhaust finishers affect fuel economy?

The impact on fuel economy is typically negligible. Any potential changes in fuel consumption are often outweighed by driving habits and other variables. Performance-oriented modifications to the entire exhaust system may yield more noticeable fuel economy improvements.

Question 5: Can an exhaust finisher void a vehicle’s warranty?

The installation of an exhaust finisher alone is unlikely to void a vehicle’s warranty, unless it directly causes damage to the exhaust system or other components. However, modifications that affect emissions control systems may void warranty coverage related to those systems. Consult the vehicle manufacturer’s warranty policy for clarification.

Question 6: How often should exhaust finishers be cleaned and maintained?

Regular cleaning and maintenance are recommended to preserve the appearance and longevity of exhaust finishers. Cleaning with appropriate metal polishes or cleaners every few months helps remove dirt, grime, and oxidation. Periodic inspection of clamps and welds ensures continued installation security.

In conclusion, while exhaust finishers primarily serve aesthetic purposes, selecting durable materials, ensuring proper fitment, and adhering to maintenance practices are crucial for maximizing their value and lifespan.

The following section will provide a summary of the key considerations.

Conclusion

The preceding discussion has examined the multifaceted aspects of muffler tips for diesel trucks. Aesthetic considerations, corrosion resistance, sound modification, diameter compatibility, material durability, installation security, and regulatory compliance have been detailed. Each element contributes to the overall value and suitability of these aftermarket accessories.

The informed selection and proper installation of these components require careful attention to detail and adherence to established guidelines. Consideration of regional environmental factors and regulatory requirements is essential for ensuring long-term satisfaction and legal compliance. Future advancements in materials science and manufacturing techniques may further enhance the durability and performance characteristics of these products. Therefore, continuous evaluation and awareness of industry developments remain crucial.

![Why Is Your Airpod Mic Muffled? [FIX] Now! Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Why Is Your Airpod Mic Muffled? [FIX] Now! | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-219-300x200.jpg)