An exhaust system component associated with vehicles operating primarily in Texas and the surrounding region, typically features a design emphasizing durability and performance within the specific environmental conditions prevalent there. These components are often chosen to withstand the rigorous demands of diverse driving conditions, from urban commuting to extensive highway travel.

The significance of a robust exhaust system lies in its ability to efficiently manage engine emissions, contribute to fuel economy, and reduce noise pollution. Historically, the Texas automotive market has favored products capable of withstanding extreme temperatures and prolonged usage. Consequently, specialized exhaust systems offer enhanced longevity, improved engine efficiency, and contribute to maintaining regulatory compliance with emissions standards.

The subsequent sections will delve into specific product features, materials used in construction, installation considerations, and long-term maintenance practices relevant to selecting an appropriate exhaust system solution for vehicles in the region.

Guidance for Selecting and Maintaining a Vehicle Exhaust System

The following information provides essential guidelines for choosing and maintaining an exhaust system, specifically targeting considerations pertinent to vehicles operating in Texas and the surrounding areas. Attention to these points will help ensure optimal performance, longevity, and regulatory compliance.

Tip 1: Material Selection: Prioritize exhaust systems constructed from high-grade stainless steel or aluminized steel. These materials offer superior resistance to corrosion, a critical factor in humid climates or regions with road salt application.

Tip 2: Gauge Thickness: Evaluate the gauge thickness of the exhaust piping. Thicker gauge materials provide increased durability against physical damage from road debris and extended service life.

Tip 3: Welding Quality: Inspect weld quality meticulously. Robust and consistent welds are essential for preventing leaks and ensuring structural integrity under stress. Inadequate welds can compromise the system’s performance and longevity.

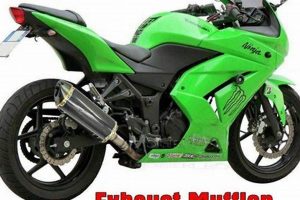

Tip 4: Muffler Design: Consider the muffler’s internal design. Chambered mufflers generally provide enhanced sound reduction, while straight-through designs prioritize performance and exhaust flow. Choose a design that aligns with the vehicle’s intended use and desired sound characteristics.

Tip 5: Catalytic Converter Compliance: Verify that the catalytic converter meets all applicable federal and state emissions standards. Non-compliant components can result in fines and hinder the vehicle’s ability to pass inspections.

Tip 6: Professional Installation: Opt for professional installation by a qualified technician. Proper installation ensures correct alignment, secure connections, and optimal performance of the system.

Tip 7: Regular Inspection: Implement a routine inspection schedule to identify potential issues early. Check for rust, leaks, damage, and loose connections. Addressing minor problems promptly can prevent more significant repairs down the line.

Consistent adherence to these guidelines will help maximize the performance and lifespan of the vehicle’s exhaust system. Selecting appropriate materials and committing to regular maintenance offers long-term benefits in terms of operational efficiency and environmental responsibility.

The subsequent sections will delve into specific maintenance procedures and troubleshooting techniques for common exhaust system issues.

1. Material Durability

Material durability directly impacts the lifespan and operational effectiveness of exhaust systems. Systems operating within Texas and surrounding regions, often subject to extreme temperatures, humidity, and varying road conditions, require robust materials to prevent premature failure. The correlation between material quality and system longevity is significant. Inferior materials are prone to corrosion, cracking, and structural weakening, leading to compromised performance and potential regulatory non-compliance. The selection of durable materials, such as high-grade stainless steel or aluminized steel, is thus paramount.

For example, coastal regions of Texas experience high humidity and saltwater exposure, accelerating corrosion in exhaust systems constructed from less resistant materials. Conversely, systems made from stainless steel exhibit superior resistance to these corrosive elements, extending their service life. Similarly, areas with significant temperature fluctuations demand materials capable of withstanding thermal stress without deformation or cracking. Improper material selection results in increased maintenance costs and potential safety hazards. Manufacturers often employ specific coatings and alloys to enhance material durability in these demanding environments.

Therefore, prioritizing material durability is a critical aspect of exhaust system selection. Understanding the specific environmental challenges prevalent in Texas and the surrounding areas is crucial for making informed decisions. Opting for materials proven to withstand these conditions ensures long-term performance, reduces the frequency of repairs, and contributes to overall vehicle reliability. Failure to consider material durability can lead to preventable system failures, increased costs, and potential environmental impacts.

2. Welding Integrity

Welding integrity is a critical factor in the performance and longevity of exhaust systems, especially those intended for operation in regions like Texas, where demanding environmental conditions prevail. Sound welds are essential for enduring both physical stress and corrosive elements. Compromised welding directly impacts system reliability and exhaust gas containment.

- Structural Strength

High-quality welds ensure structural integrity, preventing cracks and fractures under the mechanical stresses induced by engine vibration and road impacts. An exhaust system with deficient welds is susceptible to early failure, potentially leading to exhaust leaks and reduced vehicle performance. For example, a weld that fails under stress could cause sections of the system to separate, requiring costly repairs.

- Corrosion Resistance

Sound welds create a continuous, sealed barrier against corrosive elements, such as road salt and moisture. Porous or incomplete welds provide entry points for these elements, accelerating corrosion and reducing the system’s lifespan. Systems operating in humid coastal areas are particularly vulnerable to this type of degradation. Properly executed welds mitigate this risk by preventing exposure of the underlying metal to corrosive agents.

- Leak Prevention

Consistent and complete welds are imperative for preventing exhaust leaks. Even small leaks can diminish engine performance, reduce fuel efficiency, and create potentially hazardous conditions due to the escape of exhaust gases. Welding defects often manifest as pinholes or incomplete fusion, allowing gases to escape and creating a safety risk for vehicle occupants. Meticulous welding practices are thus crucial for ensuring a leak-free exhaust system.

- Material Compatibility

Proper welding techniques must account for the compatibility of the materials being joined. Dissimilar metals, if improperly welded, can create galvanic corrosion, accelerating the degradation process. Welding procedures must be tailored to the specific alloys used in the exhaust system to ensure a strong and durable bond. Incompatible welding processes can compromise the structural integrity of the system, leading to premature failure and costly repairs.

In conclusion, welding integrity plays a pivotal role in the overall performance and durability of exhaust systems. Compromised welding practices lead to reduced system lifespan, potential safety hazards, and increased maintenance costs. Therefore, selecting an exhaust system with verifiable welding quality is paramount for ensuring long-term reliability, particularly for vehicles operating in challenging environments.

3. Sound Attenuation

Sound attenuation, or the reduction of noise generated by a vehicle’s exhaust system, is a critical performance characteristic of exhaust components, particularly those marketed under the brand “lone star muffler”. Achieving effective sound attenuation involves balancing regulatory compliance, driver comfort, and vehicle performance. Different designs and materials are employed to manage the complex sound waves produced by an internal combustion engine.

- Muffler Design and Construction

The internal design of an exhaust system’s muffler plays a central role in sound attenuation. Chambered mufflers use a series of baffles to reflect and redirect sound waves, causing them to cancel each other out and reduce overall noise levels. Straight-through mufflers, conversely, prioritize exhaust flow for performance but often incorporate sound-absorbing materials, such as fiberglass or steel wool, to dampen noise. The specific construction of the muffler, including the thickness of the casing and the quality of the welds, contributes to its ability to effectively reduce sound. A “lone star muffler” employing a multi-chambered design may achieve greater noise reduction than a straight-through design, but at the potential expense of exhaust flow.

- Resonator Integration

Resonators are additional components often integrated into exhaust systems to target specific frequencies of sound. These components function by creating destructive interference, canceling out specific sound waves that contribute to unwanted noise. The strategic placement and tuning of resonators can significantly improve sound attenuation without sacrificing performance. A “lone star muffler” incorporating a tuned resonator could effectively eliminate drone, a low-frequency humming noise often associated with aftermarket exhaust systems.

- Material Selection for Sound Absorption

The materials used in the construction of a muffler influence its ability to absorb sound energy. Materials like fiberglass packing, steel wool, and ceramic fibers are commonly used to line the interior of mufflers, absorbing sound waves and converting them into heat. The density and composition of these materials affect their sound-absorbing properties and their longevity. A “lone star muffler” using high-density fiberglass packing may provide superior sound attenuation compared to a muffler with less effective sound-absorbing materials.

- Regulatory Compliance and Aftermarket Considerations

Sound attenuation is closely linked to regulatory compliance, as many jurisdictions have noise level restrictions for vehicles. Aftermarket exhaust systems, including “lone star muffler” products, must meet these regulations to be legally operated on public roads. Achieving compliance often requires careful consideration of muffler design, resonator integration, and material selection. Some aftermarket systems prioritize performance over sound attenuation, potentially exceeding noise limits, while others focus on minimizing noise levels to meet regulatory requirements. Compliance certifications and testing data provide evidence of an exhaust system’s sound attenuation capabilities.

Effective sound attenuation in a “lone star muffler”, or any exhaust system component, relies on a combination of design features, material choices, and regulatory considerations. The ideal system balances noise reduction, performance, and durability, meeting the needs of drivers while adhering to legal requirements. The increasing demand for quieter vehicles and stricter noise regulations will likely drive further advancements in sound attenuation technologies for exhaust systems.

4. Emissions Compliance

Emissions compliance is a critical element in the design and marketing of exhaust systems, including those bearing the “lone star muffler” brand. Exhaust systems are subject to stringent federal and state regulations designed to limit the release of harmful pollutants into the atmosphere. Failure to meet these standards results in legal penalties, product recalls, and damage to brand reputation. The relationship between “lone star muffler” products and emissions compliance is therefore one of essential interdependence; the former cannot exist legally or ethically without the latter. Real-world examples of non-compliant aftermarket exhaust systems demonstrate the practical significance of this understanding. Products that bypass or disable catalytic converters, for instance, release excessive levels of hydrocarbons, nitrogen oxides, and carbon monoxide, contributing to air pollution and violating federal law. The Environmental Protection Agency (EPA) actively monitors and enforces emissions regulations, imposing substantial fines on manufacturers and distributors of non-compliant exhaust systems.

The design of a compliant “lone star muffler” exhaust system involves careful consideration of several factors. These include the use of certified catalytic converters that effectively reduce pollutant levels, the maintenance of proper air-fuel ratios to ensure efficient combustion, and the minimization of exhaust leaks. Furthermore, manufacturers must conduct rigorous testing to verify that their products meet emissions standards under various operating conditions. This testing often involves dynamometer simulations and on-road evaluations. Beyond the technical aspects, manufacturers also bear the responsibility of providing clear and accurate information to consumers regarding the emissions performance of their products. This includes labeling requirements and documentation demonstrating compliance with relevant regulations. In the absence of such information, consumers risk purchasing exhaust systems that are illegal or environmentally harmful.

In summary, emissions compliance is not merely an add-on feature of a “lone star muffler” exhaust system; it is an intrinsic requirement that shapes product design, manufacturing processes, and marketing strategies. The consequences of non-compliance are severe, ranging from financial penalties to environmental damage. Understanding the importance of emissions compliance is essential for both manufacturers and consumers in the automotive industry. Challenges remain in ensuring that aftermarket exhaust systems consistently meet emissions standards, particularly given the increasing complexity of vehicle emission control systems. Addressing these challenges requires ongoing innovation, rigorous testing, and effective enforcement of regulations. The “lone star muffler” brand, and others in the industry, are expected to contribute to these efforts to maintain environmental quality and uphold legal requirements.

5. Regional Adaptability

Regional adaptability significantly influences the design and performance of automotive components, including exhaust systems marketed under the “lone star muffler” brand. This adaptability encompasses considerations specific to geographical location, climate, and prevalent driving conditions, all of which directly impact exhaust system longevity and operational effectiveness. The selection of materials, design features, and manufacturing processes must account for these regional variations to ensure optimal performance and customer satisfaction. Neglecting regional adaptability leads to premature component failure, increased maintenance costs, and potential regulatory non-compliance.

In the context of “lone star muffler”, regional adaptability manifests in several key areas. For instance, Texas and surrounding states experience high temperatures and humidity, accelerating corrosion in exhaust systems constructed from substandard materials. Consequently, “lone star muffler” products often feature enhanced corrosion resistance through the use of high-grade stainless steel or aluminized steel. Furthermore, varying terrain and driving habits necessitate robust construction to withstand physical impacts and thermal stress. Areas with frequent off-road driving or rough road conditions require thicker gauge materials and reinforced welds to prevent damage. Emission regulations also differ across state lines, requiring “lone star muffler” products to meet specific compliance standards depending on the region in which they are sold. The design and testing processes are therefore tailored to ensure adherence to these diverse regulatory requirements.

In summary, regional adaptability is an essential consideration in the design, manufacturing, and marketing of “lone star muffler” exhaust systems. Failing to account for regional climate, driving conditions, and regulatory standards results in compromised performance, reduced product lifespan, and potential legal ramifications. A comprehensive understanding of these factors enables “lone star muffler” to deliver products that meet the specific needs of its target market, enhancing customer satisfaction and maintaining a competitive advantage. Ongoing monitoring of regional trends and evolving regulatory landscapes is crucial for ensuring continued adaptability and long-term success.

Frequently Asked Questions Regarding “lone star muffler” Products

The following addresses common inquiries and clarifies essential aspects related to exhaust systems, particularly those marketed under the “lone star muffler” brand. The information provided aims to offer a comprehensive understanding of product characteristics and related considerations.

Question 1: What is the expected lifespan of a “lone star muffler” exhaust system?

The lifespan of a “lone star muffler” exhaust system varies based on several factors, including material composition, driving conditions, and maintenance practices. High-grade stainless steel systems typically offer greater longevity than aluminized steel systems. Regular inspections and prompt repairs of any identified damage contribute to extending the system’s operational life. Specific warranty information is available with the product documentation.

Question 2: Are “lone star muffler” exhaust systems compliant with emissions regulations?

“lone star muffler” exhaust systems are designed to meet applicable federal and state emissions regulations. Compliance is achieved through the integration of certified catalytic converters and adherence to stringent design standards. Detailed emissions compliance information is provided with the product specifications and warranty documentation. It remains the vehicle owner’s responsibility to ensure continued compliance with all applicable regulations.

Question 3: How does the design of a “lone star muffler” impact vehicle performance?

The design of a “lone star muffler” exhaust system affects vehicle performance by influencing exhaust flow and engine backpressure. Optimized designs enhance exhaust gas scavenging, potentially improving horsepower and fuel efficiency. The specific performance characteristics vary depending on the model and vehicle application. Independent dyno testing data is often available to quantify performance gains.

Question 4: What materials are typically used in the construction of “lone star muffler” exhaust systems?

“lone star muffler” exhaust systems are generally constructed from either stainless steel or aluminized steel. Stainless steel offers superior corrosion resistance, while aluminized steel provides a cost-effective alternative. The specific material selection depends on the product line and intended application. Detailed material specifications are included in the product descriptions.

Question 5: What are the recommended maintenance procedures for “lone star muffler” exhaust systems?

Recommended maintenance procedures include regular inspections for rust, leaks, and physical damage. Prompt repairs of any identified issues prevent further degradation of the system. Periodic cleaning with appropriate cleaning agents helps to remove contaminants and prolong the system’s lifespan. Professional installation is recommended to ensure proper fitment and optimal performance.

Question 6: Can a “lone star muffler” exhaust system affect vehicle sound levels?

“lone star muffler” exhaust systems can modify vehicle sound levels, depending on the design of the muffler and resonator components. Chambered mufflers generally provide greater sound attenuation than straight-through designs. Aftermarket exhaust systems must comply with local noise regulations. Detailed sound level information is typically provided in the product specifications.

In summary, the selection and maintenance of a “lone star muffler” exhaust system necessitate careful consideration of various factors, including material selection, emissions compliance, performance characteristics, and maintenance practices. Consulting with a qualified automotive technician is advisable to ensure optimal results.

The subsequent sections will address specific installation considerations and troubleshooting techniques.

Conclusion

This exploration has dissected various facets pertinent to “lone star muffler” exhaust systems, encompassing material durability, welding integrity, sound attenuation, emissions compliance, and regional adaptability. Consideration of these elements is crucial for informed decision-making regarding selection, maintenance, and overall performance optimization. The interdependence of these factors underscores the complexity inherent in exhaust system design and functionality.

Prudent evaluation of these considerations is essential for ensuring regulatory adherence, maximizing system lifespan, and achieving optimal vehicle performance. Further research and consultation with qualified professionals are encouraged to facilitate comprehensive understanding and informed implementation of best practices. The long-term implications of these choices extend beyond individual vehicle performance, impacting environmental sustainability and regulatory compliance within the broader automotive landscape. The informed consumer is empowered to contribute positively to both vehicle efficiency and environmental responsibility.