The components responsible for attenuating engine exhaust noise are varied in design and function. These components, designed to reduce the decibel level of internal combustion engine operation, achieve noise reduction through different internal configurations and materials. Understanding the specific characteristics of each design is key to appreciating their impact on vehicle sound profiles.

Effective noise reduction contributes significantly to vehicle comfort and compliance with noise regulations. Historically, advancements in these components have been driven by increasingly stringent environmental standards and consumer demand for quieter vehicles. Choosing an appropriate system affects both the auditory experience and regulatory adherence of vehicle operation.

The following sections will detail the primary categories of these noise-reducing components, outlining their distinct construction, performance characteristics, and typical applications, enabling a comprehensive comparison of their relative advantages and disadvantages.

Guidance on Exhaust Noise Reduction Devices

Selecting an appropriate exhaust noise reduction device requires careful consideration of vehicle application, desired sound characteristics, and regulatory compliance. The following guidelines offer insight into optimizing this selection process.

Tip 1: Determine Noise Reduction Requirements: Prior to selection, assess the specific noise level reduction needed to meet local regulations or personal preferences. Decibel meters can aid in accurately measuring existing noise levels.

Tip 2: Consider Engine Type and Size: The exhaust flow and pressure differ significantly based on engine type (inline, V-type) and displacement. Select a device rated to handle the specific engine output.

Tip 3: Evaluate Internal Construction: Absorption designs, such as those with fiberglass packing, offer broad frequency attenuation but may require periodic repacking. Reflection designs, employing baffles and chambers, offer durable performance but may exhibit narrow frequency peaks.

Tip 4: Account for Backpressure Effects: Excessive backpressure can reduce engine performance and fuel economy. Select a device designed to minimize backpressure while achieving desired noise reduction.

Tip 5: Investigate Material Selection: Stainless steel construction offers superior corrosion resistance and longevity compared to aluminized steel, particularly in harsh environments.

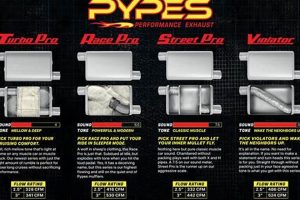

Tip 6: Evaluate Sound Characteristics: Different designs produce varying exhaust notes. Consider the desired sound profile deep rumble, smooth tone, or near-silent operation when making a selection.

Tip 7: Prioritize Professional Installation: Proper installation ensures optimal performance and longevity. Seek professional installation services to guarantee correct alignment, sealing, and support.

Careful adherence to these guidelines will facilitate the selection of an exhaust noise reduction device that effectively manages exhaust noise, optimizes engine performance, and satisfies individual preferences.

The subsequent sections of this resource will delve into specific design types and their relative performance characteristics, providing a more detailed understanding of the available options.

1. Construction Materials

Construction materials are intrinsically linked to the acoustic properties and longevity of exhaust noise attenuation devices. The materials employed directly influence sound characteristics by affecting vibration damping and resonance frequencies. For example, a device constructed from thin-gauge steel exhibits higher resonant frequencies, potentially resulting in a tinny or hollow sound. Conversely, thicker-gauge steel or stainless steel construction can dampen vibrations, leading to a deeper, more subdued exhaust note.

Material selection also plays a crucial role in durability and resistance to environmental factors. Aluminized steel, while offering cost-effectiveness, is susceptible to corrosion, particularly in regions with road salt exposure. This corrosion degrades the structural integrity of the device and can alter its internal acoustic properties over time. Stainless steel, offering superior corrosion resistance, ensures consistent performance and sound quality throughout the component’s lifespan. Certain high-performance devices incorporate titanium or Inconel alloys to withstand extreme temperatures and pressures, further enhancing durability and contributing to a distinct, often aggressive, exhaust note. Aftermarket mufflers utilize carbon fiber outer layers for aesthetics and weight reduction, with a minimal impact on sound attenuation.

The relationship between construction materials and exhaust noise attenuation device performance is therefore multifaceted. Material properties dictate sound characteristics, component durability, and overall performance. Understanding these connections is critical for making informed decisions when selecting or designing these systems, balancing cost considerations with performance requirements and longevity expectations. The choice of material will ultimately dictate the overall exhaust system tone and how well it holds up over time.

2. Internal Design

The internal design of exhaust noise attenuation devices directly dictates the sound characteristics produced. Muffler designs employ varied internal configurations to manipulate sound waves, resulting in distinct exhaust tones. Baffled designs, utilizing a series of internal partitions to reflect and redirect sound waves, typically produce a more aggressive and pronounced exhaust note. These designs often feature chambers of varying sizes and shapes, each tuned to attenuate specific frequencies. The placement, size, and shape of these baffles and chambers directly influence the resulting sound profile, creating a cause-and-effect relationship between internal design and sound output.

Absorption-based designs, on the other hand, utilize sound-absorbing materials such as fiberglass packing to dampen noise. These designs generally produce a quieter and more subdued exhaust note, as the packing material absorbs sound energy across a broader frequency spectrum. The density and type of packing material influence the effectiveness of sound attenuation and the overall tone. Straight-through designs, often found in performance applications, minimize restrictions on exhaust flow while still providing some degree of noise reduction through strategically placed perforations and packing material. These designs typically yield a louder, more resonant sound compared to baffled or chambered mufflers. An example of a vehicle that demonstrates this is the Subaru WRX, which often have straight-through mufflers for better exhaust flow.

Understanding the influence of internal design on sound characteristics is crucial for selecting an exhaust noise attenuation device that meets specific performance and auditory requirements. Different designs cater to distinct preferences, ranging from near-silent operation to aggressive performance tones. Knowledge of these principles allows for informed decision-making, enabling individuals to tailor exhaust systems to their desired sound profile. The effectiveness in mitigating noise depends on understanding how sounds are manipulated based on the internal design selected.

3. Sound Attenuation

Sound attenuation, the reduction of sound intensity, is the primary function of exhaust noise attenuation devices. Various designs achieve this through different physical principles, directly influencing the resultant sound profile and overall effectiveness.

- Absorption Materials and Frequency Damping

Certain designs, such as those utilizing fiberglass or mineral wool packing, absorb sound energy by converting it into heat. This is particularly effective at damping mid- to high-frequency sounds, resulting in a smoother, less harsh exhaust note. The type and density of the absorption material directly influence the frequencies attenuated. For example, tightly packed, high-density fiberglass absorbs higher frequencies more effectively.

- Baffle Geometry and Sound Wave Cancellation

Baffled systems reduce noise through destructive interference. Sound waves are reflected off baffles within the device, and strategically designed chambers cause these waves to collide out of phase, resulting in partial or complete cancellation. The dimensions and placement of the baffles are critical for achieving specific frequency attenuation. Incorrect geometry can lead to amplified frequencies instead of attenuation. For instance, a badly tuned chamber can resonate, creating a droning sound at a specific engine RPM.

- Resonator Chambers and Helmholtz Principles

Resonator chambers, often employed in conjunction with other attenuation techniques, operate on the Helmholtz principle. These chambers are tuned to a specific frequency and attenuate sound by creating a destructive interference effect at that frequency. This is commonly used to reduce unwanted drone at particular engine speeds. For instance, a resonator chamber can be designed to specifically target the 120Hz drone often experienced at highway cruising speeds.

The interplay of these mechanismsabsorption, wave cancellation, and resonancedefines the effectiveness of sound attenuation in exhaust noise attenuation devices. Selecting the appropriate design hinges on understanding how these principles interact to achieve the desired reduction in sound intensity and overall sound characteristics.

4. Engine Backpressure

Engine backpressure, the resistance to exhaust flow exiting the engine’s cylinders, is intricately linked to the design of exhaust noise attenuation devices. Different designs inherently present varying levels of backpressure, influencing engine performance and sound characteristics. A highly restrictive device, while potentially providing significant noise reduction, increases backpressure, impeding the engine’s ability to expel exhaust gases efficiently. This impediment can lead to reduced power output, decreased fuel economy, and increased engine operating temperatures. The magnitude of this effect varies based on engine design and the specific characteristics of the device used. For example, a heavily baffled muffler on a small displacement engine may create a noticeable reduction in horsepower, while the same muffler on a larger engine may have a negligible impact. The practical significance of understanding backpressure is apparent in selecting the appropriate device for a specific vehicle, balancing noise reduction needs with performance considerations.

Conversely, a device with minimal internal restrictions, such as a straight-through design, minimizes backpressure and maximizes exhaust flow. This configuration can enhance engine performance, particularly at higher RPMs, but often results in increased exhaust noise levels. Performance vehicles frequently utilize such designs to optimize power output, accepting the trade-off of a louder exhaust note. Aftermarket exhaust systems specifically designed for performance often prioritize reduced backpressure over noise attenuation, reflecting this principle. However, excessively low backpressure can also be detrimental, potentially leading to scavenging issues where exhaust gases are not efficiently removed from the cylinders, particularly at lower engine speeds. Finding the optimal balance is crucial for maximizing both performance and fuel efficiency.

In summary, engine backpressure is a critical consideration in the selection and design of exhaust noise attenuation devices. The choice of device influences the engine’s ability to breathe, impacting performance, fuel economy, and operating temperatures. Balancing the need for noise reduction with the desire for optimal engine performance requires a thorough understanding of the relationship between internal design, backpressure, and engine characteristics. The appropriate design will vary depending on the specific application and the desired balance between these competing factors.

5. Vehicle Application

Vehicle application exerts a significant influence on the selection of appropriate exhaust noise attenuation devices. The specific vehicle type, intended use, and regulatory environment necessitate different design considerations to achieve optimal performance and noise control.

- Passenger Cars and Noise Regulations

Passenger vehicles are subject to stringent noise regulations, dictating maximum permissible sound levels. Muffler selection must prioritize effective noise reduction while minimizing backpressure to maintain fuel efficiency and performance. Designs incorporating multiple chambers and absorption materials are common in passenger car applications to meet these requirements. The specific regulations vary by region, further influencing the selection process; for example, European regulations are often stricter than those in North America.

- Performance Vehicles and Exhaust Flow

Vehicles designed for performance often prioritize exhaust flow over noise reduction. Straight-through designs or those with minimal internal restrictions are favored to maximize engine power. While these designs typically produce louder exhaust notes, the performance gains are deemed more important. Aftermarket performance exhaust systems often incorporate features such as electronic valves to control exhaust noise levels dynamically, allowing for quieter operation during normal driving conditions and unrestricted flow during performance driving.

- Heavy-Duty Trucks and Durability

Heavy-duty trucks operating in demanding environments require rugged and durable exhaust noise attenuation devices. Designs utilizing thick-gauge steel and robust construction are essential to withstand the stresses of heavy loads and harsh conditions. Noise regulations also apply to commercial vehicles, necessitating effective noise reduction strategies. Often, larger volume mufflers utilizing a combination of baffles and absorption material are employed to achieve both noise reduction and durability.

- Motorcycles and Sound Character

Motorcycle applications often emphasize sound character alongside noise reduction. Many riders seek a specific exhaust note that complements the motorcycle’s aesthetics and riding experience. Aftermarket exhaust systems for motorcycles often offer a range of sound profiles, from deep rumble to high-pitched scream. Regulations still apply, however, requiring that exhaust systems meet specific noise limits, typically enforced through periodic inspections. This often leads to complex muffler designs that attempt to balance sound character with regulatory compliance.

The varied requirements of different vehicle applications underscore the importance of considering the intended use and operating environment when selecting exhaust noise attenuation devices. Matching the device to the vehicle’s specific needs ensures optimal performance, regulatory compliance, and driver satisfaction. For Example, a hybrid car’s muffler needs are significantly different to a race car because their vehicle applications are drastically different.

6. Sound Frequency

Sound frequency, measured in Hertz (Hz), represents the number of sound wave cycles per second and is a fundamental component of exhaust sound characteristics. Different muffler types selectively attenuate or amplify specific frequency ranges, shaping the overall auditory experience. An exhaust system’s effectiveness is, therefore, frequency-dependent, with varying designs excelling at mitigating different portions of the audible spectrum. For instance, a low-frequency rumble, often desired in performance applications, is typically generated by exhaust systems that minimize backpressure and feature large-volume resonators tuned to those frequencies. Conversely, high-frequency hisses and whistles can be suppressed through designs incorporating dense absorption materials.

The practical significance of understanding sound frequency lies in tailoring the exhaust note to meet specific needs or preferences. Engineers often use frequency analysis tools to measure exhaust sounds and identify dominant frequencies contributing to undesirable noise characteristics, such as drone or raspiness. This data informs the design of custom mufflers or resonators targeted at attenuating those specific frequencies. For example, some vehicle applications might prioritize minimizing low-frequency booming to reduce cabin noise, while others might focus on enhancing high-frequency crackles to accentuate a sporty exhaust note. Aftermarket systems frequently allow tunability, employing adjustable valves or interchangeable resonators to modify the sound profile.

Challenges arise in achieving broad-spectrum noise reduction without compromising engine performance. Muffler designs effective at attenuating a wide range of frequencies often introduce significant backpressure, negatively impacting power output. Advanced techniques, such as active noise cancellation or Helmholtz resonators, offer potential solutions by selectively targeting problematic frequencies without impeding exhaust flow. The ultimate goal is a balanced system that achieves the desired sound characteristics while maintaining optimal engine efficiency, necessitating a nuanced understanding of sound frequency and its interplay with muffler design.

7. Performance Longevity

Performance longevity, concerning exhaust noise attenuation devices, is directly tied to both the design and materials used, affecting sound characteristics over time. The type of muffler influences its susceptibility to degradation, subsequently altering its sound-dampening abilities. For instance, mufflers employing fiberglass packing experience a gradual reduction in sound attenuation as the packing material breaks down due to heat and vibration. This breakdown results in a louder exhaust note and a shift in frequency characteristics. Conversely, chambered mufflers, relying on baffles for sound wave interference, maintain a more consistent sound profile over their lifespan, provided the baffles remain structurally intact. The correlation between muffler type and performance longevity is thus significant in predicting how sound output will evolve with prolonged use.

Material selection critically impacts the durability and, consequently, the performance longevity of these devices. Aluminized steel, while cost-effective, is prone to corrosion, especially in regions with high road salt usage. Corrosion compromises structural integrity, leading to leaks and alterations in the internal geometry, drastically affecting sound attenuation. Stainless steel, offering enhanced corrosion resistance, extends the lifespan of the device and maintains a more consistent sound profile over time. Titanium or Inconel alloys, employed in high-performance applications, withstand extreme temperatures and pressures, further ensuring consistent performance and sound characteristics under demanding conditions. Maintenance, such as periodic inspections for corrosion or damage, also contributes to extending the performance longevity of exhaust noise attenuation systems. Neglecting such maintenance accelerates degradation and leads to premature failure.

The interplay between muffler type, material selection, and maintenance practices defines the performance longevity of exhaust noise attenuation devices. Understanding these factors is crucial for predicting how the sound characteristics of a vehicle will evolve over time and for making informed decisions about muffler selection and maintenance. Prioritizing durable materials and implementing regular inspections ensures sustained sound attenuation and optimal performance throughout the system’s lifespan. The practical significance lies in minimizing the need for frequent replacements and maintaining consistent sound quality, impacting both the vehicle’s performance and auditory experience.

Frequently Asked Questions

The following section addresses common inquiries regarding the characteristics, function, and selection of exhaust noise attenuation devices. The information presented aims to provide clarity on key aspects of these systems.

Question 1: What is the primary function of an exhaust muffler?

The primary function of an exhaust muffler is to reduce the noise generated by an internal combustion engine as exhaust gases are expelled. This is achieved through various internal designs that manipulate sound waves to minimize their amplitude before exiting the system.

Question 2: How do different muffler types affect vehicle performance?

Different muffler types impact vehicle performance primarily through the level of backpressure they introduce into the exhaust system. Highly restrictive mufflers can impede exhaust flow, potentially reducing horsepower and fuel efficiency. Less restrictive designs may enhance performance but typically at the expense of increased noise levels.

Question 3: What materials are commonly used in muffler construction, and how do they differ?

Common muffler construction materials include aluminized steel, stainless steel, and, in high-performance applications, titanium or Inconel alloys. Aluminized steel offers cost-effectiveness but is susceptible to corrosion. Stainless steel provides enhanced corrosion resistance and longevity. Titanium and Inconel offer exceptional durability and heat resistance for demanding applications.

Question 4: How does the internal design of a muffler influence its sound characteristics?

The internal design of a muffler, such as the presence of baffles, chambers, or absorption materials, dictates its sound characteristics. Baffled mufflers produce a more aggressive tone, while absorption mufflers offer quieter operation. Resonators can be incorporated to target specific frequencies and reduce drone.

Question 5: What factors should be considered when selecting a muffler for a specific vehicle?

Factors to consider when selecting a muffler include the vehicle type, intended use, regulatory noise limits, desired sound characteristics, and budget. Performance applications may prioritize exhaust flow, while passenger vehicles often require quieter operation to comply with regulations.

Question 6: How can the longevity of an exhaust muffler be maximized?

The longevity of an exhaust muffler can be maximized through material selection, proper installation, and regular maintenance. Choosing corrosion-resistant materials like stainless steel, ensuring secure mounting to prevent stress, and periodically inspecting for damage or corrosion contribute to extended service life.

The information provided addresses fundamental questions regarding exhaust noise attenuation devices. Further research and consultation with qualified professionals are recommended for specific applications.

The subsequent section will present a glossary of key terms related to exhaust noise attenuation and acoustics.

Muffler Types and Sounds

This exploration of muffler types and sounds has illuminated the intricate relationship between design, material, and acoustic properties in exhaust noise attenuation. The differentiation among various types reveals the diverse strategies employed to manage sound waves, reflecting distinct approaches to noise reduction and performance enhancement. From baffled designs to absorption-based systems, each configuration presents unique advantages and disadvantages, influencing both the auditory experience and the engine’s operational efficiency.

A thorough understanding of these principles empowers informed decision-making in selecting exhaust systems tailored to specific vehicle applications and desired sound profiles. Continued advancement in materials and designs is anticipated, promising further optimization of exhaust noise attenuation while minimizing performance trade-offs. As environmental regulations and consumer expectations evolve, the ongoing refinement of these components remains a critical aspect of automotive engineering.

![Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-396-300x200.jpg)

![Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-328-300x200.jpg)