A component designed to reduce the noise emitted from an internal combustion engine, specifically tailored for vehicles, is a critical part of the exhaust system. These devices utilize internal chambers and baffling to attenuate sound waves produced during engine operation. For example, a performance version might enhance exhaust flow while still maintaining acceptable noise levels.

Such a noise-reduction element plays a vital role in adhering to environmental regulations and ensuring driver and community well-being. Historically, advancements in these devices have paralleled engine technology, with improvements focused on efficiency, durability, and sound quality. The selection of a suitable device is influenced by factors such as vehicle type, engine size, and desired performance characteristics.

The subsequent sections will delve into the construction, functionality, selection criteria, and potential performance enhancements associated with these automotive components, providing a detailed understanding of their operation and impact.

Guidance on Noise Reduction System Management

The following outlines essential advice concerning the maintenance, optimization, and regulatory compliance of automotive noise reduction systems.

Tip 1: Routine Inspection: Conduct regular visual inspections for signs of corrosion, physical damage, or leaks. Compromised integrity can lead to increased noise output and reduced efficiency.

Tip 2: Secure Mounting: Ensure all mounting points are securely fastened. Vibration and movement can loosen connections, resulting in rattles and potential system failure.

Tip 3: Exhaust Leak Detection: Promptly address any detected exhaust leaks. These not only elevate noise levels but also pose safety risks due to the potential for carbon monoxide exposure.

Tip 4: Material Compatibility: When replacing components, verify material compatibility with the existing exhaust system. Dissimilar metals can cause galvanic corrosion, shortening the system’s lifespan.

Tip 5: Regulatory Compliance: Be aware of and adhere to all applicable noise regulations in the operating jurisdiction. Modifications exceeding established limits can result in fines and vehicle restrictions.

Tip 6: Performance Optimization: Consider the vehicle’s intended use when selecting a noise reduction system. Performance-oriented systems often prioritize exhaust flow over maximum noise attenuation.

Tip 7: Professional Installation: For complex installations or modifications, engage a qualified technician to ensure proper fitment and functionality.

Adhering to these guidelines promotes optimal performance, extends system longevity, and contributes to a safer, more compliant operating environment.

The subsequent section will summarize the preceding points, reinforcing the importance of proactive management of automotive noise reduction systems.

1. Noise reduction effectiveness

The primary function of an automotive muffler is the attenuation of engine exhaust noise. Noise reduction effectiveness, therefore, represents a critical performance metric. Within the context of vehicular exhaust systems, this metric is directly linked to regulatory compliance and community noise levels. A muffler that fails to adequately reduce noise emissions can result in legal penalties and negatively impact the surrounding environment. For instance, vehicles exceeding established decibel limits may be subject to fines or be prohibited from operating in certain areas. In residential zones, inadequate noise reduction from a vehicle’s exhaust system can disrupt the peace and contribute to noise pollution.

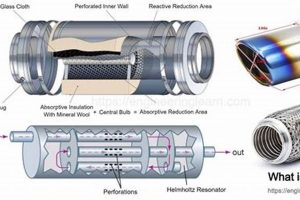

Effective noise reduction relies on a combination of internal baffling, resonance chambers, and sound-absorbing materials within the muffler’s design. The specific configuration of these elements influences the degree of noise attenuation achieved. Mufflers employing reactive noise cancellation utilize chambers to reflect sound waves, causing destructive interference that reduces the overall sound pressure level. Absorptive mufflers, on the other hand, incorporate materials such as fiberglass or steel wool to convert sound energy into heat, thereby diminishing noise output. The choice of technology and design parameters will dictate the overall noise reduction effectiveness.

In summary, the noise reduction effectiveness of a muffler is essential for legal compliance, environmental responsibility, and community consideration. It depends on internal design characteristics and the materials utilized. Optimization requires careful consideration of both performance and regulatory constraints, which makes this parameter fundamentally important in muffler design and selection.

2. Material Durability

Material durability is a critical factor in determining the lifespan and performance consistency of exhaust system components. The selection of appropriate materials directly impacts the resilience of a muffler to environmental stressors and operational demands, thereby affecting its long-term effectiveness.

- Corrosion Resistance

Exposure to road salts, moisture, and exhaust gases can induce corrosion in muffler materials. The choice of corrosion-resistant alloys, such as stainless steel or aluminized steel, mitigates this risk, extending the component’s service life. Inferior materials are susceptible to rust and degradation, leading to structural failure and increased noise emissions. For instance, a muffler constructed from low-grade steel might exhibit significant corrosion within a year of exposure to winter road conditions, compromising its noise reduction capabilities and necessitating premature replacement.

- Thermal Stability

Mufflers are subjected to high operating temperatures due to the passage of hot exhaust gases. Material durability, in this context, pertains to the material’s ability to withstand elevated temperatures without undergoing deformation, cracking, or weakening. Alloys with superior thermal stability maintain their structural integrity and acoustic properties even under extreme thermal cycling. For example, certain grades of stainless steel exhibit excellent resistance to thermal fatigue, preserving their performance characteristics over prolonged periods of high-temperature operation.

- Mechanical Strength

The physical integrity of a muffler is challenged by vibrations, impacts from road debris, and internal pressure fluctuations. High-strength materials resist deformation and cracking under these stresses, ensuring the muffler remains structurally sound. Insufficient mechanical strength can result in weld failures, baffle damage, and overall structural collapse. A heavy-duty muffler designed for off-road vehicles, for example, requires robust materials capable of withstanding significant impacts and vibrations without compromising its functionality.

- Abrasion Resistance

Road debris, such as rocks and gravel, can impact the exterior of a muffler, causing abrasion and erosion of protective coatings. Materials with high abrasion resistance maintain their surface finish and prevent the underlying metal from being exposed to corrosive elements. This is particularly important for mufflers positioned in vulnerable locations beneath the vehicle. For example, a ceramic coating applied to a muffler’s exterior can significantly improve its resistance to abrasion and extend its visual appeal over time.

In conclusion, material durability is intrinsically linked to the longevity, performance, and reliability of exhaust system components. Selecting materials that exhibit excellent corrosion resistance, thermal stability, mechanical strength, and abrasion resistance is paramount for ensuring optimal performance and minimizing the need for frequent replacements. Careful consideration of these material properties is essential for maximizing the value and effectiveness of noise reduction solutions.

3. Exhaust Flow Design

Exhaust flow design within a muffler directly influences engine performance and noise attenuation. The internal configuration of a muffler, particularly its baffling and chamber arrangements, determines the path and velocity of exhaust gases. An efficient exhaust flow design minimizes backpressure, which can impede engine performance by restricting the expulsion of exhaust gases from the cylinders. Excessive backpressure reduces engine power, fuel efficiency, and throttle response. Conversely, a poorly designed exhaust flow can lead to insufficient noise reduction, failing to meet regulatory standards or community expectations. The objective is to strike a balance between maximizing exhaust gas velocity and minimizing sound propagation.

The practical application of exhaust flow design principles is evident in various muffler technologies. Straight-through mufflers, for example, offer minimal restriction to exhaust flow, often employed in performance vehicles seeking to maximize power output. However, they typically provide less noise reduction compared to baffled mufflers. Baffled mufflers utilize a series of internal chambers and deflectors to redirect and slow down exhaust gases, increasing sound attenuation but potentially increasing backpressure. Chambered designs are complex to optimize, requiring meticulous engineering to balance noise reduction and exhaust flow. Another instance is the use of Helmholtz resonators within muffler systems, designed to cancel out specific frequencies of sound, effectively targeting and reducing unwanted noise emissions while preserving overall exhaust flow efficiency. The choice of design depends on the vehicle’s intended use and the desired performance characteristics.

In conclusion, exhaust flow design is integral to a muffler’s overall effectiveness, impacting both engine performance and noise reduction. Achieving an optimal balance requires careful consideration of the specific vehicle application, regulatory requirements, and performance objectives. An effective design minimizes backpressure to maintain engine efficiency while simultaneously attenuating noise to acceptable levels. Challenges arise in meeting conflicting demands, necessitating advanced engineering and testing methodologies. Understanding the relationship between exhaust flow design and noise attenuation is crucial for developing high-performing, environmentally responsible exhaust systems.

4. Regulatory Compliance

Adherence to established noise regulations is a fundamental aspect of exhaust system design and performance. Governmental bodies and local authorities implement noise standards to mitigate the impact of vehicular noise pollution on public health and environmental quality. The design, manufacture, and sale of exhaust components, including mufflers, are subject to stringent testing and certification processes to ensure compliance with these regulations. Failure to meet the prescribed noise limits can result in legal penalties for manufacturers, retailers, and vehicle operators. For example, numerous municipalities mandate noise level testing for vehicles, with fines levied for exceeding established decibel thresholds. Therefore, regulatory compliance is not merely a legal obligation but an essential element in responsible product development and operation.

The practical implications of regulatory compliance extend beyond legal considerations. Exhaust systems that fail to meet noise standards can contribute to community noise pollution, impacting the quality of life for residents in urban and suburban areas. Increased noise levels can lead to sleep disturbances, stress, and other adverse health effects. As such, designing and installing exhaust systems that conform to noise regulations is a crucial step in promoting public well-being. The development of noise-reduction technologies and the adoption of best practices in muffler design directly contribute to reducing the environmental impact of vehicle operation. For example, the utilization of advanced sound-absorbing materials and optimized baffling configurations can significantly reduce noise emissions without compromising engine performance.

In summary, regulatory compliance is inextricably linked to the responsible design, manufacturing, and operation of exhaust systems. Adherence to noise regulations is essential for avoiding legal penalties, minimizing environmental impact, and protecting public health. The commitment to meeting or exceeding established noise standards represents a crucial aspect of corporate social responsibility and demonstrates a dedication to promoting a cleaner and quieter environment. The integration of regulatory requirements into every stage of product development ensures that noise reduction remains a central design criterion, rather than an afterthought.

5. Vehicle Compatibility

The suitability of an exhaust noise reduction device for a specific vehicle, known as vehicle compatibility, is critical to its performance and longevity. An ill-fitting or incorrectly specified device can lead to reduced noise attenuation, compromised engine performance, and potential damage to the exhaust system or surrounding components. For example, installing a muffler designed for a compact car on a heavy-duty truck may result in insufficient noise reduction and premature failure due to the higher exhaust volume and pressures. The device must match the vehicle’s engine displacement, exhaust system configuration, and mounting points to ensure proper function and secure installation.

A primary cause of incompatibility stems from variations in exhaust pipe diameter and routing across different vehicle models. A device designed for a specific diameter may not create a secure seal with a different-sized exhaust pipe, leading to exhaust leaks and increased noise levels. Similarly, differences in mounting bracket locations and orientations can complicate installation, potentially requiring modifications that compromise the structural integrity of the device or the vehicle. The practical significance of ensuring vehicle compatibility is evident in the reduction of installation time, the prevention of premature component failure, and the maintenance of optimal engine performance. For instance, using a universal-fit muffler may seem cost-effective initially, but the need for extensive modifications and the risk of subpar performance often outweigh the initial savings.

In summary, vehicle compatibility is a non-negotiable factor in the selection and installation of an exhaust system component. Proper fitment ensures optimal noise reduction, preserves engine performance, and prevents damage to the vehicle. Addressing compatibility challenges requires careful consideration of vehicle specifications, including engine displacement, exhaust system configuration, and mounting requirements. This understanding leads to better system functionality and a reduction in maintenance or repairs.

6. Installation Integrity

Installation integrity, in the context of an exhaust system noise reduction device, refers to the correctness and stability of its physical integration with the vehicle. This is not a separate attribute but an essential element of its functionality. Improper installation can negate the design advantages inherent in the device. Securely attaching the device to the exhaust system, with leak-free seals and robust mounting, directly affects the reduction of noise as intended by its manufacturer. Consider, for example, a scenario where a device designed for optimal noise reduction is installed with loose connections. Exhaust gas leakage will occur, increasing noise output above compliance levels and potentially damaging surrounding components due to heat and vibration. This illustrates the cause-and-effect relationship between installation integrity and the intended performance.

The importance of installation integrity extends beyond noise reduction. A poorly installed device can introduce backpressure, impeding engine performance and fuel efficiency. Vibrations and stress on the device, resulting from insecure mounting, lead to premature failure, requiring costly repairs or replacements. Furthermore, an improperly installed system might violate emissions regulations or compromise vehicle safety. As a practical application, a qualified technician utilizes specialized tools and techniques to ensure proper alignment, tightening torque, and sealing of all connections. They may also perform exhaust leak tests to verify the installation’s integrity. The use of correct hangers, clamps, and gaskets, along with adherence to manufacturer specifications, are important.

In summary, installation integrity is inextricably linked to the successful operation of an exhaust system device. Compromised installation results in reduced performance, increased noise, potential damage, and regulatory non-compliance. Attention to detail during the installation process, coupled with the use of appropriate tools and expertise, is critical for maximizing the lifespan and effectiveness. This understanding is essential for ensuring both environmental responsibility and vehicle performance.

Frequently Asked Questions

The following addresses prevalent inquiries regarding the selection, functionality, and maintenance of automotive noise reduction devices.

Question 1: What is the primary function of an automotive muffler?

The core function is to attenuate noise generated by the engine’s combustion process. This is achieved through internal chambers and baffling that disrupt sound waves, reducing their intensity before exiting the exhaust system. This process allows the vehicle to comply with noise regulations.

Question 2: How does muffler design impact engine performance?

The internal configuration affects exhaust flow. A restrictive design can increase backpressure, hindering engine efficiency and power output. Conversely, a free-flowing design may reduce noise attenuation. Optimal design achieves a balance between these two factors.

Question 3: What materials are commonly used in muffler construction?

Common materials include aluminized steel and stainless steel. Stainless steel offers superior corrosion resistance and durability, while aluminized steel provides a cost-effective alternative with adequate protection in many environments.

Question 4: How does one determine if a muffler is compliant with local noise regulations?

Compliance typically involves adhering to established decibel limits. Verification often requires professional testing using specialized equipment. Documentation from the manufacturer may also indicate compliance with specific standards.

Question 5: What are the signs of a failing muffler?

Indications include increased exhaust noise, rattling sounds, visible rust or damage, and reduced engine performance. Any of these symptoms warrant inspection and potential replacement.

Question 6: Can a muffler be modified to improve performance or sound?

Modifications may alter exhaust flow and noise characteristics. However, such alterations may also violate noise regulations or compromise vehicle emissions controls. Modifications should be undertaken with caution and in accordance with applicable laws.

In summary, noise reduction devices are essential for managing exhaust noise, ensuring regulatory compliance, and maintaining vehicle performance. Understanding their function, design, and maintenance requirements promotes responsible vehicle operation.

The following section addresses the performance enhancement potential of a specific exhaust system.

Patriot Muffler

The preceding exploration of exhaust noise reduction devices has underscored the multifaceted nature of these components. The discussion has extended from the fundamental principles of noise attenuation and the crucial selection of materials to the intricate considerations of exhaust flow design, regulatory compliance, vehicle compatibility, and installation integrity. Emphasis has been placed on the interconnectedness of these factors, revealing that optimal performance necessitates a holistic approach encompassing design, implementation, and maintenance.

Recognizing the significance of a well-engineered and properly installed exhaust system component is vital for both individual vehicle owners and the broader community. Continued advancements in noise reduction technologies and a commitment to responsible vehicle operation will contribute to a quieter, healthier environment. Vigilance in maintenance and adherence to regulatory guidelines are paramount in ensuring long-term compliance and minimizing the impact of vehicular noise pollution.

![Best Kinney Muffler: Reviews & Alternatives [Year] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Best Kinney Muffler: Reviews & Alternatives [Year] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-52-300x200.jpg)