The performance exhaust component designed for specific high-performance vehicles within a particular automotive brand serves to manage and reduce engine noise while optimizing exhaust flow. As a critical element of the vehicle’s exhaust system, it is engineered to meet both legal noise restrictions and the performance demands of the vehicle. For example, certain models known for their enhanced power output often utilize a specialized variant tailored for improved sound and flow characteristics.

The significance of this component lies in its ability to balance noise levels with performance gains. It is often an area of focus for enthusiasts seeking to enhance the vehicle’s auditory experience and overall power. Historically, its design has evolved significantly to meet increasingly stringent emissions standards and the desire for improved engine efficiency. Its selection influences the perceived quality and driving experience of a performance vehicle.

Understanding the design, materials, and performance characteristics of this exhaust component is crucial for those considering modifications or replacements. Subsequent sections will delve into specific aspects such as material selection, installation considerations, and potential performance impacts when considering aftermarket alternatives.

Considerations for Enhanced Performance

Optimizing the vehicle’s exhaust system requires careful consideration of several factors to ensure both performance gains and compliance with local regulations. This section offers key points to consider during the evaluation and modification process.

Tip 1: Material Selection: Opt for components constructed from high-grade stainless steel. This material provides superior resistance to corrosion, extending the lifespan of the component and maintaining consistent performance over time.

Tip 2: Diameter Considerations: Evaluate the exhaust pipe diameter relative to the engine’s output. An inappropriately sized diameter can hinder exhaust flow, negating potential performance benefits. Consult with a qualified technician to determine the optimal diameter.

Tip 3: Sound Level Regulations: Prior to any modifications, research local noise ordinances. Installing an aftermarket component that exceeds decibel limits can result in fines or vehicle impoundment. Investigate options that offer adjustable sound dampening.

Tip 4: Professional Installation: Engaging a qualified technician for installation is highly recommended. Incorrect installation can lead to exhaust leaks, reduced performance, and potential damage to other vehicle components.

Tip 5: Performance Mapping: After installation, consider a dyno tune to optimize engine performance. This ensures the engine is properly calibrated to take advantage of the improved exhaust flow, resulting in increased horsepower and torque.

Tip 6: Warranty Implications: Modifying the exhaust system may void certain aspects of the vehicle’s warranty. Thoroughly review warranty documentation and consult with the manufacturer or dealer regarding potential impacts before proceeding.

Tip 7: Emissions Compliance: Ensure that any modifications to the exhaust system comply with local emissions regulations. Removing catalytic converters or installing non-compliant components can result in failed emissions tests and legal penalties.

Careful planning and execution are crucial when enhancing the exhaust system. By considering these factors, owners can achieve desired performance improvements while maintaining compliance and vehicle reliability.

The following section will address specific product recommendations and a comparison of aftermarket options, offering insights to aid in the selection process.

1. Performance

The term “performance,” in the context of an exhaust system component, directly relates to its capacity to enhance engine output, improve fuel efficiency, and modify the vehicle’s overall driving experience. The design of the exhaust system profoundly influences engine backpressure; a more efficient system reduces backpressure, allowing the engine to expel exhaust gases more freely. This results in increased horsepower and torque, particularly at higher RPMs. For instance, an aftermarket component engineered for enhanced flow can measurably increase a vehicle’s horsepower, as demonstrated through dyno testing.

The performance characteristics are not solely defined by horsepower gains. The design also impacts throttle response and the overall responsiveness of the vehicle to driver inputs. A well-designed component, optimized for exhaust flow, can improve throttle sensitivity, making the vehicle feel more agile and responsive. Furthermore, the reduction in engine strain achieved through improved exhaust flow can contribute to enhanced fuel economy, especially under demanding driving conditions. The selection of materials also plays a role; stainless steel, for example, provides durability and resistance to corrosion, ensuring consistent performance over time.

In summary, “performance” is a multifaceted attribute inextricably linked to an efficient exhaust component. It encompasses power gains, throttle response, fuel efficiency, and long-term reliability. An understanding of these interconnected elements is vital for making informed decisions regarding exhaust system upgrades, ensuring that the selected component aligns with the vehicle’s intended use and the owner’s performance objectives. The challenges lie in balancing these elements with noise regulations and emissions compliance.

2. Sound characteristics

The sound characteristics emanating from the high-performance exhaust system are a critical aspect of the driving experience. The design directly influences the auditory signature, which can range from a subtle rumble to an aggressive roar. Specific construction features, such as internal baffling and chamber size, are deliberately engineered to shape the exhaust note. For example, a system with fewer baffles typically produces a louder, more aggressive sound, while a more restrictive design will result in a quieter, more refined tone. Understanding these design principles is essential for matching the exhaust sound to driver preference and ensuring compliance with local noise regulations.

The importance of the sound characteristics extends beyond mere aesthetics. For some drivers, the auditory feedback provides essential information about the engine’s performance. A well-tuned exhaust note can enhance the connection between driver and machine, contributing to a more engaging driving experience. Aftermarket manufacturers often invest significant resources in sound engineering, using advanced acoustic modeling techniques to create exhaust systems that deliver a desired sound profile without compromising performance. Practical applications include systems designed for track use, which prioritize maximum sound output, and those intended for street driving, which aim for a balance between performance and noise control.

In summary, the sound characteristics are an integral component, significantly impacting the perception and enjoyment of the vehicle. By carefully considering design features and acoustic properties, drivers can select an exhaust system that delivers the desired sound quality, enhancing the overall driving experience. Challenges in this area lie in balancing performance gains with noise regulations and individual preferences. As technology advances, it is expected that new materials and designs will further refine the ability to sculpt the exhaust sound, creating systems that are both audibly pleasing and environmentally responsible.

3. Material durability

Material durability is a critical factor in the performance and longevity of any performance exhaust component. The exhaust system, including components such as the specific muffler under consideration, is exposed to extreme conditions: high temperatures, corrosive exhaust gases, road debris, and varying environmental factors. The selection of durable materials directly impacts the component’s ability to withstand these stresses and maintain its structural integrity and performance characteristics over time. A component constructed from inferior materials is prone to premature failure, leading to exhaust leaks, reduced performance, and costly repairs. The cause-and-effect relationship is clear: inadequate material selection results in diminished component lifespan and compromised vehicle performance.

The material commonly selected for these applications is stainless steel, specifically grades like 304 or 409. These alloys offer a balance of corrosion resistance, high-temperature strength, and weldability. For example, a system fabricated from 304 stainless steel will exhibit superior resistance to rust and oxidation compared to a system constructed from aluminized steel, particularly in regions with harsh winter climates where road salt is prevalent. Another practical example is the degradation of welds due to thermal cycling. A high-quality stainless steel with proper welding techniques minimizes the risk of weld failure and ensures structural stability. Manufacturers that prioritize material durability typically subject their products to rigorous testing, including thermal shock tests, salt spray tests, and vibration analyses, to validate their long-term performance.

In conclusion, material durability is an indispensable consideration when assessing any exhaust component. The investment in a system constructed from high-quality, durable materials translates to long-term reliability, consistent performance, and reduced maintenance costs. The practical significance of this understanding lies in the prevention of premature failure and the preservation of the vehicle’s performance characteristics over its lifespan. The industry challenges lie in the balance between material cost and durability, but prioritizing high-quality materials ultimately yields a superior product with enhanced longevity.

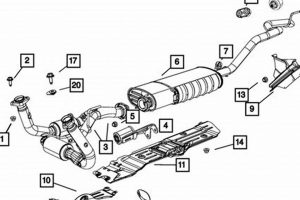

4. Installation complexity

The installation complexity associated with an exhaust component is a significant factor influencing both the cost and ultimate performance of the system. Replacing a factory exhaust system, particularly with an aftermarket performance component, requires a degree of mechanical aptitude and specialized tools. The more complex the installation, the greater the potential for errors that can compromise performance, void warranties, or even damage other vehicle components. Aftermarket components, while designed to enhance performance, often deviate from the factory’s design, potentially requiring modifications to the vehicle’s undercarriage or exhaust hangers to ensure proper fitment. This complexity has a direct cause-and-effect relationship with the overall cost of the upgrade, as professional installation services become necessary to mitigate the risk of errors. The absence of proper installation leads to exhaust leaks, rattling, reduced performance gains, and potential damage to the catalytic converter or other emission control devices.

The relative simplicity or complexity of an installation process is closely tied to the components design and the target vehicle. Some aftermarket components are designed as direct bolt-on replacements, minimizing the need for extensive modifications. Others may require cutting, welding, or the modification of existing exhaust hangers, increasing the skill level and time required for proper installation. As an example, performance components, designed for certain high-performance vehicles with specific exhaust routing configurations, might necessitate removal of underbody panels or heat shields to access the factory exhaust system. The more intricate the process, the higher the likelihood that specialized tools such as a pipe cutter, welder, or vehicle lift will be required. Practical application of this understanding involves a thorough assessment of the components installation instructions and the installers skill level prior to undertaking the replacement process.

In summary, the complexity of installation is a critical consideration when selecting an aftermarket exhaust component. It directly impacts the cost, performance, and long-term reliability of the system. Assessing the installer’s skill level, evaluating the components design, and understanding the specific requirements of the target vehicle are essential steps in ensuring a successful installation. Challenges associated with installation complexity include the potential for errors, warranty implications, and the need for specialized tools. Prioritizing proper installation mitigates these risks and ensures that the component delivers its intended performance benefits.

5. Emissions compliance

Emissions compliance is a critical consideration when evaluating the legality and environmental impact of any exhaust system component, including those marketed for performance vehicles. Modifying the exhaust system can alter its emissions characteristics, potentially violating federal and local regulations.

- Catalytic Converter Retention

The presence and functionality of catalytic converters are central to emissions compliance. Catalytic converters reduce harmful pollutants in exhaust gases. Removing or disabling these converters is illegal and results in increased emissions of hydrocarbons, carbon monoxide, and nitrogen oxides. Any replacement component must integrate functioning catalytic converters, if originally equipped, to maintain compliance. For vehicles where the original unit integrates this essential component, aftermarket options must adhere to all emission standards to remain compliant.

- Sound Level Restrictions

While primarily associated with noise, excessive exhaust sound can indirectly relate to emissions compliance. Some jurisdictions have sound level restrictions for vehicles, and exceeding these limits can result in fines or mandatory repairs. Although not directly an emissions issue, excessively loud exhaust systems often indicate modifications that could compromise emissions control components or their effectiveness, leading to failures during inspection.

- CARB Certification

In states like California, the California Air Resources Board (CARB) sets stringent emissions standards. Any aftermarket exhaust component intended for use on pollution-controlled vehicles must receive a CARB Executive Order (EO) number to demonstrate compliance. This certification process involves rigorous testing to ensure the component does not increase emissions beyond permissible levels. Without a CARB EO number, the component is illegal for use on vehicles registered in California and other states that adopt California emissions standards. This also applies to this performance exhaust component.

- Oxygen Sensor Compatibility

Oxygen sensors play a crucial role in monitoring exhaust gas composition and providing feedback to the engine control unit (ECU) for optimal fuel mixture. Modifying the exhaust system can affect the placement or functionality of oxygen sensors, potentially leading to inaccurate readings and increased emissions. Proper installation and compatibility with existing oxygen sensors are essential for maintaining emissions compliance. An incompletely sealed exhaust can cause unmeasured oxygen to enter the system, creating imbalances.

These facets underscore the importance of careful consideration of emissions regulations when modifying an exhaust system. Owners need to verify the legality of any aftermarket component, ensuring it meets federal, state, and local emissions standards. Failure to do so can result in fines, failed emissions tests, and potential vehicle impoundment. Therefore, selecting a product that retains stock emission components and functionality becomes crucial to ensure the owner is not in violation. The burden of ensuring the unit has proper certification rests on the end user.

6. Cost effectiveness

The cost effectiveness of performance exhaust components necessitates a comprehensive evaluation that extends beyond the initial purchase price. This assessment incorporates factors such as durability, performance gains, installation costs, and potential long-term maintenance expenses. Achieving optimal value demands a balance between upfront investment and the sustained benefits derived from the exhaust component. The focus here will be on identifying what factors make these components cost-effective.

- Initial Purchase Price vs. Material Quality

Lower-priced options may appear attractive initially; however, these often utilize lower-grade materials that are susceptible to corrosion and premature failure. For instance, an exhaust component constructed from aluminized steel may offer a lower upfront cost compared to stainless steel. However, stainless steel offers superior corrosion resistance and a longer lifespan, leading to reduced replacement costs over time. This long-term durability contributes significantly to the component’s cost effectiveness.

- Installation Costs and Complexity

The complexity of installation directly influences the overall cost. Direct bolt-on replacements generally incur lower installation costs compared to systems requiring modifications or specialized tools. An example is a modular exhaust system designed for straightforward installation versus a custom-fabricated system that requires professional welding and fitting. The labor costs associated with complex installations can significantly increase the total expenditure, diminishing the component’s cost effectiveness.

- Performance Gains and Fuel Efficiency

The tangible performance gains resulting from an exhaust system upgrade contribute to its perceived value. Improved horsepower, torque, and throttle response enhance the driving experience. Additionally, some systems can improve fuel efficiency under specific driving conditions. A real-world example is the potential for increased fuel economy on long highway drives due to reduced backpressure. These performance-related benefits contribute to the overall cost effectiveness by providing measurable improvements in vehicle performance and operating expenses.

- Long-Term Maintenance and Warranty

Maintenance requirements and warranty coverage directly impact the long-term cost of ownership. Exhaust components with robust warranties and minimal maintenance needs offer enhanced cost effectiveness. For example, a system with a lifetime warranty against defects provides peace of mind and reduces the risk of unexpected repair expenses. Conversely, components requiring frequent maintenance or lacking adequate warranty protection can incur additional costs, diminishing their overall value.

The true cost effectiveness of an exhaust component is determined by a holistic assessment of initial price, durability, installation costs, performance benefits, and long-term ownership expenses. Careful consideration of these factors enables consumers to make informed decisions that maximize value and ensure sustained satisfaction with their investment.

Frequently Asked Questions

This section addresses common inquiries regarding performance exhaust components, focusing on factors influencing selection, installation, and long-term performance.

Question 1: What distinguishes a performance muffler from a standard muffler?

Performance variants are engineered to reduce exhaust backpressure, enhancing engine output and throttle response. Standard mufflers prioritize noise reduction over performance, often employing more restrictive designs.

Question 2: Will installing a performance muffler void a vehicle’s warranty?

The installation may void portions of the vehicle’s warranty related to the exhaust system or components directly affected by the modification. Consult warranty documentation and the vehicle manufacturer for clarification.

Question 3: How does the selection of materials impact the longevity?

Materials, such as stainless steel, exhibit superior corrosion resistance compared to aluminized steel. This translates to a longer lifespan and sustained performance, particularly in harsh environments.

Question 4: What is the significance of CARB certification for a performance muffler?

CARB certification indicates that the component meets California Air Resources Board emissions standards. In California, and states adopting California standards, a CARB-certified component is required for legal street use.

Question 5: Does the diameter of the exhaust piping influence performance?

Yes, an appropriately sized exhaust pipe diameter optimizes exhaust flow. An undersized diameter can restrict flow, negating potential performance gains, while an oversized diameter can reduce exhaust velocity and negatively affect low-end torque.

Question 6: Is professional installation necessary for a performance muffler?

Professional installation is recommended to ensure proper fitment, prevent exhaust leaks, and avoid potential damage to vehicle components. Incorrect installation can compromise performance and void warranties.

Selecting a performance exhaust component requires careful consideration of factors such as warranty implications, material selection, emissions compliance, and installation requirements. Consulting with qualified professionals is advisable to ensure optimal results.

The following section will provide recommendations for specific performance exhaust component brands, highlighting their features and performance characteristics.

In Closing

This exploration has detailed the critical aspects of the performance exhaust component for specific vehicle applications. Careful evaluation of materials, design characteristics, installation considerations, and emissions compliance is essential for informed decision-making. The interplay between performance enhancement, sound quality, and regulatory adherence must be carefully weighed to realize the full potential of an exhaust upgrade while maintaining vehicle integrity.

Ultimately, the selection and integration of an appropriate component represent a commitment to both enhancing the driving experience and upholding responsible vehicle operation. Continued advancements in materials science and acoustic engineering promise further refinements in exhaust technology, reinforcing the importance of staying informed and prioritizing informed choices. Adherence to established standards and best practices remains paramount in the pursuit of optimized vehicle performance and enduring value.