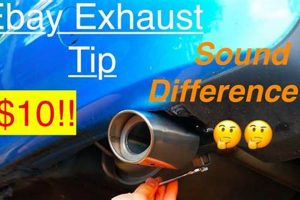

The auditory characteristic emanating from a vehicle’s exhaust system, specifically modified for enhanced engine performance, is the focus. This sound profile, often associated with turbocharged engines, represents a departure from standard factory exhaust notes, typically exhibiting a more pronounced and aggressive tone. For instance, an aftermarket component engineered to reduce backpressure in a forced-induction engine can alter the overall auditory experience.

The perceived value lies in its ability to communicate performance enhancements and mechanical modifications. Historically, the emphasis on this auditory signature has evolved in parallel with advancements in automotive engineering and the increasing popularity of performance vehicles. Furthermore, this particular aspect contributes to the overall driving experience, particularly for automotive enthusiasts who appreciate the aural feedback associated with increased power and responsiveness.

Subsequent discussion will explore the underlying principles of exhaust system design, the various types of aftermarket components used to achieve a desired auditory effect, and the regulatory considerations surrounding vehicle noise emissions.

Enhancing the Auditory Experience

The following points provide guidance on optimizing the sound characteristics of a vehicle’s exhaust system, particularly in the context of turbocharged engines. These recommendations address both performance and desired sound profiles.

Tip 1: Material Selection: Stainless steel alloys offer superior durability and resistance to corrosion compared to aluminized steel. Stainless steel enhances longevity, preserving the integrity of the exhaust system and maintaining consistent sound quality over time.

Tip 2: Diameter Optimization: Employing an exhaust pipe diameter appropriate for the engine’s displacement and power output is critical. Undersized pipes restrict exhaust flow, while oversized pipes can reduce exhaust velocity, negatively impacting both performance and sound characteristics.

Tip 3: Resonator Integration: Incorporating resonators into the exhaust system reduces unwanted frequencies and drone, resulting in a cleaner, more refined sound. The placement and type of resonator significantly influence the final auditory output.

Tip 4: Muffler Design Considerations: Muffler design directly impacts the overall sound profile. Straight-through designs offer minimal restriction and aggressive sound, while chambered designs provide greater sound attenuation and a more subdued tone. Selecting the appropriate design is essential for achieving the desired acoustic result.

Tip 5: Welding Quality: Ensure all exhaust system components are joined using high-quality welding techniques. Poor welds can create leaks, compromising performance and introducing undesirable noises.

Tip 6: Professional Installation: Engaging a qualified professional for exhaust system installation ensures proper fitment, alignment, and sealing. Correct installation is paramount for optimal performance and minimizing the risk of leaks or vibrations.

Adherence to these guidelines facilitates a balanced approach to exhaust system modification, optimizing both performance and the desired auditory experience.

The following section will cover the legal and regulatory aspects associated with exhaust system modifications.

1. Auditory Performance Enhancement

Auditory performance enhancement, in the context of turbocharged vehicles, represents a deliberate modification of the exhaust system to produce a more pronounced and aurally stimulating sound profile. This process often involves aftermarket mufflers specifically designed to alter the exhaust note, aligning it with a perception of increased power and performance.

- Frequency Modification

Aftermarket mufflers often incorporate designs that alter the frequencies present in the exhaust stream. This can involve attenuating specific frequencies to reduce drone or amplifying others to create a more aggressive sound. For example, a muffler might be designed to emphasize lower frequencies, resulting in a deeper, more resonant tone. The selection of materials and internal chamber designs significantly impacts frequency modification.

- Amplitude Amplification

Amplitude, or loudness, is another key aspect. Performance mufflers often reduce backpressure, allowing for increased exhaust gas flow. This, in turn, can result in a louder overall exhaust note. However, responsible amplification is crucial to avoid exceeding legal noise limits or creating an excessively harsh sound. Examples include straight-through muffler designs that maximize flow and volume.

- Harmonic Enhancement

Harmonics are the overtones that contribute to the richness and complexity of a sound. Performance mufflers can be designed to enhance specific harmonics, creating a more distinctive and appealing auditory signature. The internal baffling and resonance chambers within the muffler play a crucial role in shaping the harmonic content. Certain designs can lead to a more melodious sound profile.

- Resonance Tuning

Managing resonance is vital to eliminating unwanted drone and creating a clean, well-defined exhaust note. Resonators are often integrated into exhaust systems to counteract specific resonant frequencies. The placement and design of these resonators are critical for achieving optimal sound quality. A well-tuned resonance system results in a smoother, more pleasant listening experience.

These facets of auditory performance enhancement collectively contribute to the overall perception of a vehicle’s performance capabilities. While subjective preferences vary, the underlying principles of frequency modification, amplitude amplification, harmonic enhancement, and resonance tuning are essential for achieving a balanced and desirable auditory experience. These changes alter the exhaust note to suggest or signify an enhanced power train, aligning the sound with the expectation of a more potent driving experience.

2. Backpressure Reduction

Backpressure reduction is fundamentally linked to the acoustic properties associated with modified exhaust systems in turbocharged vehicles. The factory-installed exhaust systems are often designed to prioritize noise reduction and emissions control, which inherently introduce a degree of exhaust flow restriction. This restriction, or backpressure, can impede the turbocharger’s efficiency and overall engine performance. Aftermarket components, specifically mufflers designed to minimize backpressure, offer an alternative exhaust pathway.

The cause-and-effect relationship is straightforward: reducing backpressure facilitates quicker turbo spool-up and improved engine breathing, resulting in increased horsepower and torque. This alteration in exhaust flow characteristics inevitably affects the sound produced by the exhaust system. A muffler designed for minimal backpressure typically exhibits a less restrictive internal structure, which allows exhaust gases to flow more freely. This freedom results in a louder, more aggressive exhaust note, often perceived as a deeper, more resonant sound. As an example, a straight-through muffler design, devoid of restrictive baffles or chambers, will drastically reduce backpressure compared to a chambered muffler, simultaneously increasing the exhaust volume and altering the tonal quality. The perceived change in auditory output becomes a tangible representation of the performance enhancement attributed to the reduced backpressure.

In summary, backpressure reduction is a critical element in achieving both performance gains and a distinctive sound profile in turbocharged vehicles. The design of the muffler directly influences the level of backpressure and the resulting acoustic characteristics. While increased volume and a more aggressive tone are often desired outcomes, understanding the relationship between backpressure, exhaust flow, and sound generation is crucial for achieving a balanced and optimized system. However, excessive backpressure reduction without proper tuning and consideration for emissions can lead to detrimental effects, underscoring the importance of a holistic approach to exhaust system modification.

3. Frequency Modulation

Frequency modulation, in the context of turbo muffler sound, refers to the intentional alteration of the frequency components within the exhaust note to achieve a desired auditory characteristic. This process involves selectively amplifying or attenuating specific frequencies to create a distinct and often more aggressive sound profile.

- Harmonic Tuning

Harmonic tuning focuses on manipulating the overtones present in the exhaust sound. By emphasizing specific harmonics, the muffler can create a richer and more complex auditory texture. For instance, a muffler designed to accentuate the higher harmonics may produce a crisper, more metallic sound, while emphasizing lower harmonics can result in a deeper, more resonant tone. This manipulation directly influences the perceived quality and character of the turbo muffler sound.

- Drone Mitigation

Drone, characterized by low-frequency resonance, is a common issue with aftermarket exhaust systems. Frequency modulation techniques are employed to mitigate drone by attenuating the problematic frequencies. Resonators and strategically placed chambers within the muffler are designed to cancel out or dampen these frequencies, resulting in a smoother and more comfortable auditory experience. This process is critical for maintaining an acceptable sound level inside the vehicle cabin.

- Bandwidth Shaping

Bandwidth shaping involves controlling the range of frequencies present in the exhaust note. A wider bandwidth results in a broader, more diverse sound, while a narrower bandwidth creates a more focused and concentrated tone. Muffler designs that incorporate varying chamber sizes and internal structures can effectively shape the bandwidth, influencing the overall character of the turbo muffler sound. For example, a muffler with a wide bandwidth may produce a more aggressive and attention-grabbing sound, while a narrower bandwidth may result in a more refined and subtle tone.

- Interference Patterns

Interference patterns within the exhaust stream also play a crucial role. Using chambers and specific baffling inside the muffler cause sound waves to constructively or destructively interfere with each other. This affects how specific frequencies present themselves outside the exhaust. This creates unique sounds, specific to designs of the system.

The deliberate manipulation of frequency components is a central aspect of achieving a desired turbo muffler sound. These facets demonstrate how a complex system of modifying sound is related to performance gains, as well as an overall desired driving experience. Frequency modulation is a carefully tuned process balancing performance, aural perception, and regulatory compliance.

4. Resonance Control

Resonance control is integral to shaping the auditory characteristics associated with a vehicles modified exhaust system, particularly in turbocharged applications. Uncontrolled resonance manifests as drone a low-frequency, often monotonous sound within the vehicle’s cabin, detracting from the driving experience. Aftermarket exhaust systems, designed to enhance performance and alter the exhaust note, frequently exhibit resonance issues if not properly engineered. The objective of resonance control is to attenuate these undesirable frequencies, ensuring the modified exhaust system delivers a pleasing and performance-oriented sound without compromising driver comfort. A cause-and-effect relationship is evident: modifications to the exhaust system can alter resonant frequencies, necessitating the implementation of resonance control measures to counteract negative auditory consequences. The importance is in creating an exhaust note which balances a perception of power while maintaining driver and passenger comfort.

Resonators, strategically positioned within the exhaust system, are the primary means of achieving resonance control. These devices are designed to cancel out specific frequencies that contribute to drone. Examples include Helmholtz resonators, which utilize a tuned chamber to counteract a specific frequency through destructive interference, and quarter-wave resonators, which employ a pipe length equivalent to one-quarter of the wavelength of the target frequency. Effective implementation involves accurate frequency analysis and precise placement of resonators to achieve optimal cancellation. An improperly designed or positioned resonator may be ineffective or, in some cases, exacerbate the problem. Many high-end aftermarket exhaust systems utilize sophisticated modeling software to accurately predict resonant frequencies and optimize resonator design and placement. The practical significance of this understanding is in creating an aftermarket component that is desirable and saleable.

In conclusion, resonance control is a critical engineering consideration in the development of aftermarket exhaust systems for turbocharged vehicles. Successful implementation mitigates drone and ensures the desired auditory characteristics are achieved without compromising driver comfort. Challenges remain in accurately predicting resonant frequencies across varying engine operating conditions, necessitating advanced modeling techniques and rigorous testing. Proper control measures ensures the overall sound remains pleasant.

5. Material Composition

Material composition is intrinsically linked to the auditory characteristics of a turbocharged vehicle’s exhaust system. The materials used in constructing the muffler and exhaust piping directly influence the sound’s timbre, resonance, and overall durability. Cause-and-effect is evident: the inherent properties of a material dictate how it vibrates and transmits sound waves, directly impacting the audible output. Material composition serves as a critical component in shaping the final auditory profile, contributing significantly to the perception of performance and quality. For example, stainless steel, commonly employed in aftermarket exhaust systems, offers superior corrosion resistance and a brighter, more metallic sound compared to aluminized steel. The choice of material dictates the longevity of the system, as well as its sonic properties. The practical significance of understanding these factors enables informed decisions in component selection, aligning material properties with desired auditory and performance goals.

Further analysis reveals that material thickness and density play equally important roles. Thicker-gauge materials tend to produce deeper, more resonant tones, while thinner materials may result in a higher-pitched, more raspy sound. The internal structure of the muffler, constructed from specific materials, interacts with the exhaust flow, creating interference patterns and shaping the frequency response. Consider titanium exhaust systems, which are significantly lighter than steel counterparts. The unique acoustic properties of titanium, coupled with its reduced weight, contribute to a distinctive high-pitched and often louder exhaust note. This demonstrates a further interrelationship between materials, structural design, weight reduction, performance and associated sound output.

In summary, material composition is a defining factor in shaping a turbo muffler sound. The selection of materials affects the sound, and overall system durability. Challenges remain in predicting complex acoustic interactions within exhaust systems, necessitating advanced simulation techniques and empirical testing. Understanding this link facilitates the creation of optimized components in order to achieve a more desirable auditory experience.

Frequently Asked Questions

The following addresses commonly asked questions concerning the modification of exhaust systems in turbocharged vehicles, focusing on the resulting auditory characteristics and performance implications.

Question 1: Does altering the exhaust system on a turbocharged vehicle void the manufacturer’s warranty?

Modifications to the exhaust system may, depending on the specific terms of the warranty and applicable regulations, impact the manufacturer’s warranty coverage. Consult the warranty documentation and local laws for definitive guidance. Furthermore, it’s crucial to assess the potential impact of any modification on emissions control systems, as tampering with these systems may violate environmental regulations.

Question 2: What is the expected lifespan of an aftermarket muffler compared to a factory-installed unit?

The lifespan of an aftermarket muffler is contingent upon several factors, including the material composition, construction quality, and environmental conditions. Stainless steel mufflers generally exhibit greater durability than aluminized steel units. However, driving conditions, such as exposure to road salt and extreme temperatures, can accelerate corrosion and reduce lifespan. Proper maintenance, including regular inspections and cleaning, can prolong the service life of any muffler.

Question 3: How does exhaust backpressure affect the performance of a turbocharged engine?

Excessive exhaust backpressure impedes the turbocharger’s ability to efficiently expel exhaust gases, reducing engine performance. Conversely, insufficient backpressure can negatively impact low-end torque. Striking a balance between minimizing backpressure and maintaining optimal exhaust gas velocity is crucial for maximizing overall engine performance.

Question 4: Are there legal restrictions on the permissible sound levels of vehicle exhaust systems?

Many jurisdictions have noise regulations that impose limits on the maximum permissible sound levels emitted by vehicles. These regulations are often enforced through roadside inspections or testing. Exceeding the established noise limits can result in fines or other penalties. Therefore, it’s essential to ensure that any modifications to the exhaust system comply with local noise ordinances.

Question 5: What are the primary differences between chambered and straight-through muffler designs?

Chambered mufflers utilize a series of internal chambers to attenuate sound waves, typically resulting in a quieter and more subdued exhaust note. Straight-through mufflers, conversely, offer minimal restriction to exhaust flow and produce a louder, more aggressive sound. The choice between these designs depends on the desired auditory characteristics and performance goals.

Question 6: Can modifications to the exhaust system negatively affect fuel economy?

While modifications to the exhaust system are primarily intended to enhance performance and alter the sound, they can indirectly influence fuel economy. Reducing exhaust backpressure can improve engine efficiency and potentially increase fuel economy. However, aggressive driving behavior, often associated with performance modifications, can offset any potential fuel savings.

In conclusion, the alteration of exhaust systems on turbocharged vehicles requires careful consideration of various factors, including warranty implications, material durability, backpressure effects, legal restrictions, muffler design characteristics, and fuel economy. A comprehensive understanding of these aspects is crucial for making informed decisions and achieving the desired performance and auditory goals.

The next section will cover case studies.

Conclusion

The preceding exploration has illuminated the multifaceted aspects of “turbo muffler sound,” encompassing its impact on auditory experience, performance enhancement, and compliance with regulatory standards. It is apparent that achieving a desirable auditory profile requires a nuanced understanding of frequency modulation, resonance control, material composition, and backpressure dynamics. Optimization of these elements is essential for creating a balanced and effective exhaust system modification.

Continued research and technological advancements are anticipated to further refine the science of shaping exhaust acoustics, offering enhanced capabilities for tailoring the auditory signature of turbocharged vehicles. Diligent adherence to established guidelines and regulations remains paramount to ensure modifications contribute positively to both performance and environmental responsibility. Further exploration into case studies and real-world examples will solidify understanding of this complex system.

![Fix: Why Does My Right AirPod Sound Muffled? [Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Does My Right AirPod Sound Muffled? [Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-19-300x200.jpg)