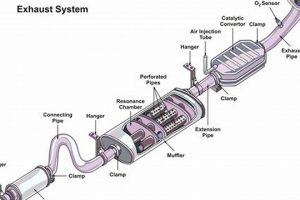

The removal of the rear-most sound dampening component on a specific BMW model, the E90 335i, is a modification performed to alter the vehicle’s exhaust note. This process entails disconnecting and removing the factory-installed component, often replacing it with straight piping or leaving the exhaust system open after the resonator. The resulting effect is a noticeable increase in exhaust volume and a change in tone.

This modification is undertaken by enthusiasts seeking to enhance the auditory experience of their vehicle. It can provide a more aggressive and pronounced sound, particularly during acceleration. Historically, modifications of this nature have been a common practice to improve perceived performance and provide a more visceral connection to the driving experience. However, considerations regarding noise levels and local regulations are important aspects of this alteration.

The subsequent sections will delve into specific effects on exhaust sound, potential performance implications, regulatory and legal considerations, and installation procedures related to this popular modification.

Modifying a vehicle’s exhaust system requires careful consideration and adherence to best practices. The following tips outline essential aspects to remember when considering the deletion of the rear sound dampening element on the BMW E90 335i.

Tip 1: Research Local Regulations: Before initiating any modifications, investigate local noise ordinances and vehicle regulations. Many jurisdictions have restrictions on vehicle sound levels, and non-compliance can result in fines or required remediation.

Tip 2: Consider Sound Characteristics: Removing the specified component will significantly alter the exhaust note. Previewing sound clips or recordings of similar modifications on comparable vehicles can provide an understanding of the resulting sound profile.

Tip 3: Evaluate Potential Performance Impact: While the modification primarily affects sound, there may be minor alterations in exhaust flow. Evaluate whether these potential changes align with overall performance goals and if they necessitate complementary modifications, such as ECU tuning.

Tip 4: Ensure Proper Installation: Whether self-installing or employing a professional, proper welding and secure mounting are critical. Exhaust leaks can compromise performance and safety. Verify all connections are airtight and structurally sound.

Tip 5: Factor in Resonance and Drone: Deleting the sound dampening element can introduce unwanted resonance or drone at certain engine speeds. Research potential solutions, such as adding resonators or strategically placed sound dampening materials, to mitigate these effects.

Tip 6: Consider the Material: If fabricating replacement piping, select materials compatible with the existing exhaust system (typically stainless steel) to prevent corrosion and ensure longevity.

The above tips emphasize the importance of informed decision-making and careful execution. Attention to legal considerations, sound preferences, potential performance impacts, and proper installation will contribute to a satisfactory outcome.

The subsequent section will explore potential downsides and alternatives related to modifying the exhaust system of the E90 335i.

1. Increased Exhaust Volume

The removal of the muffler on an E90 335i directly causes a significant increase in exhaust volume. The factory-installed component is specifically designed to attenuate sound waves produced by the engine’s combustion process. Its absence allows these sound waves to propagate with minimal obstruction, resulting in a louder exhaust note. This increase is typically most pronounced during acceleration and at higher engine speeds, as the volume of exhaust gases increases proportionally. The importance of understanding this connection lies in managing potential noise pollution and complying with local regulations. For instance, some municipalities have decibel limits for vehicle exhaust, and exceeding these limits can lead to fines.

Beyond regulatory compliance, the increased exhaust volume also affects the driver and the surrounding environment. Drivers may perceive the enhanced sound as more engaging and sporty. However, prolonged exposure to excessive noise levels can contribute to driver fatigue. Furthermore, in residential areas, the increased exhaust volume can be disruptive to residents, potentially leading to complaints and legal issues. The modification’s effect is not only about enhancing sound; it also raises concerns about managing the negative aspects of noise pollution in everyday scenarios.

In summary, the increased exhaust volume is a direct and predictable consequence. While it may appeal to enthusiasts seeking a more aggressive sound, its impact on regulatory compliance, driver comfort, and the surrounding environment must be carefully considered. A responsible approach involves assessing the potential benefits against the potential drawbacks, ensuring adherence to applicable laws, and acknowledging the effect on others.

2. Potential Performance Change

The alteration of exhaust flow dynamics following a rear sound dampening component removal on the E90 335i precipitates a potential, albeit often minimal, change in engine performance. The premise hinges on the reduction of backpressure within the exhaust system. Backpressure, in controlled amounts, can aid low-end torque; however, excessive backpressure can impede the scavenging of exhaust gases from the cylinders, thereby reducing overall efficiency. The removal of the rear component aims to alleviate potential excess backpressure. In practice, the effect on a stock E90 335i engine is usually not substantial. Dyno testing often reveals marginal gains, if any, within the normal operating range of the vehicle. A notable example might be a slight improvement in throttle response or a minor increase in horsepower at higher RPMs, but these effects are often within the margin of error of testing equipment and are rarely perceptible to the average driver.

The potential for performance improvement is heightened when the modification is coupled with other enhancements, such as aftermarket downpipes, high-flow catalytic converters, or ECU tuning. These combined modifications offer a more comprehensive approach to optimizing exhaust flow and engine management, allowing the engine to capitalize on the reduced backpressure. For instance, pairing the exhaust modification with an ECU tune that specifically targets increased boost pressure and fuel delivery can unlock more significant power gains. In such cases, the component removal becomes a contributing factor within a larger performance-oriented strategy. It is also relevant to consider that any perceived improvement might stem from the placebo effect, influenced by the altered sound characteristics of the exhaust system.

In conclusion, while the isolated removal of the rear sound dampening component on an E90 335i presents a potential for performance change, the actual impact is typically minimal on a stock vehicle. Significant gains are generally realized only when combined with other performance-enhancing modifications and appropriate engine tuning. The focus should remain on a holistic approach to performance optimization, with an awareness of the limitations of isolated modifications and the importance of accurate performance measurement.

3. Legality and Regulations

The practice of removing the rear sound dampening component from an E90 335i exhaust system intersects directly with a complex web of legal and regulatory constraints. These constraints, enacted at federal, state, and local levels, are designed to mitigate noise pollution and ensure vehicle compliance with established standards. The potential for non-compliance mandates a thorough understanding of the applicable regulations prior to undertaking any such modifications.

- Federal Noise Standards

The United States Environmental Protection Agency (EPA) establishes federal noise standards for motor vehicles, although these standards primarily target manufacturers. While these federal standards do not directly prohibit the modification of existing exhaust systems, they lay the groundwork for state and local regulations. The EPA mandates that vehicles meet specific noise emission levels at the time of manufacture, and alterations that compromise these original design parameters may be subject to scrutiny under state and local laws. Enforcement, however, primarily rests at the state and local level.

- State Noise Laws

Individual states implement their own noise laws, which vary significantly in stringency and enforcement. Some states have specific decibel limits for vehicle exhaust, while others have broader prohibitions against excessively loud or disruptive vehicle noise. For instance, a state may prohibit any modification that renders the vehicle louder than it was originally certified. Furthermore, visual inspection during vehicle safety inspections may identify the absence of the factory-installed sound dampening component, potentially leading to failure. Penalties for non-compliance range from fines to requirements for restoring the vehicle to its original configuration.

- Local Noise Ordinances

Local municipalities, including cities and counties, often enact their own noise ordinances that further restrict vehicle sound levels. These ordinances frequently target specific times of day or residential areas, imposing stricter limits than state regulations. Enforcement typically falls to local law enforcement officers, who may use subjective judgment or decibel meters to assess compliance. The absence of the factory-installed component increases the likelihood of exceeding these local noise limits, particularly in noise-sensitive environments. Ignorance of local ordinances is not a defense, emphasizing the need for thorough research.

- Vehicle Inspection Programs

Many states mandate periodic vehicle safety and emissions inspections. During these inspections, the presence and functionality of required emissions control equipment are evaluated. While the rear sound dampening component is not directly related to emissions, its absence can raise suspicion regarding other potentially illegal modifications. Inspectors may fail vehicles if they determine that the exhaust system has been altered in a manner that violates state or federal regulations, even if the vehicle passes emissions tests. The subjectivity of inspection criteria adds an element of uncertainty, as interpretations may vary between inspection facilities.

In conclusion, the legality of the E90 335i rear sound dampening component removal is contingent upon adherence to a complex interplay of federal guidelines, state statutes, and local ordinances. Failure to comply with these regulations can result in significant penalties and necessitate costly remediation efforts. Thorough research of applicable laws and potential implications is paramount before undertaking this modification. Furthermore, even if the modification is technically legal in a given jurisdiction, its impact on the community should be carefully considered.

4. Installation Complexity

The perceived simplicity of the process belies the underlying technical considerations related to the removal of the rear sound dampening component on the E90 335i. While the core task involves detaching the factory-installed component and replacing it with either straight piping or leaving the exhaust system open, the successful and safe execution of this modification requires a degree of skill and adherence to proper procedures. The primary complexity arises from the need to create secure and leak-free connections. Welding, if required, necessitates proficiency in the relevant welding techniques and access to appropriate equipment. Ill-prepared welding can result in exhaust leaks, which can degrade performance, create undesirable noise, and potentially introduce harmful exhaust gases into the passenger compartment. An example of such an event would be the improper welding of replacement piping, leading to pinhole leaks that are difficult to detect but degrade the system’s performance and safety.

Beyond welding, the proper alignment and support of the exhaust system are critical. The absence of the factory-installed component can alter the structural integrity of the remaining exhaust system, potentially leading to increased stress on other components, such as exhaust hangers or catalytic converters. Proper support, either through custom brackets or modifications to existing hangers, is necessary to prevent premature failure. Moreover, the selection of appropriate materials for replacement piping is essential. Using incompatible metals can lead to galvanic corrosion, weakening the exhaust system over time. Stainless steel is generally recommended for its durability and resistance to corrosion. An understanding of these material properties and the potential for electrochemical reactions is a practical application of metallurgical knowledge in the context of this modification.

In summary, while the concept is straightforward, the removal of the rear sound dampening component on the E90 335i presents several challenges related to welding quality, exhaust system alignment, material selection, and long-term structural integrity. A failure to address these complexities can result in performance degradation, safety risks, and premature failure of the exhaust system. Consequently, undertaking this modification requires a careful assessment of one’s skills and access to appropriate tools and expertise. If uncertain, professional installation is advisable to ensure a safe and reliable outcome.

5. Alternative Exhaust Options

The appeal of the modification to remove the rear sound dampening element on the E90 335i stems from a desire for enhanced auditory feedback and, in some cases, perceived performance gains. However, commercially available, complete exhaust systems offer a structured alternative to this more drastic approach. These alternatives are designed and engineered as complete systems, optimizing exhaust flow and sound characteristics in a controlled manner, while addressing some of the potential drawbacks associated with component removal. The selection and integration of components are carefully considered to provide a specific sound profile, minimize drone, and maintain acceptable noise levels, often validated through dyno testing for quantifiable performance benefits. A typical example is a cat-back exhaust system designed for the E90 335i, which replaces the entire exhaust system from the catalytic converters backward. Such systems are often constructed of stainless steel, mandrel-bent for smooth flow, and incorporate resonators and mufflers to achieve a specific sound. This structured alternative contrasts with the more variable and less predictable results of a component removal.

Complete exhaust systems present several advantages over simply removing a component. These systems are engineered to meet specific performance and sound criteria, thereby increasing the likelihood of a predictable and desirable outcome. They are often designed to be bolt-on replacements, simplifying installation and minimizing the need for custom fabrication. Furthermore, reputable manufacturers often provide documentation regarding performance gains and sound levels, providing a tangible basis for comparison. Examples of this are readily available through dyno charts and sound clips offered by exhaust system manufacturers. Some brands also provide options for active exhaust valves, enabling users to adjust the exhaust note based on driving conditions or personal preferences. This adjustability provides a level of control unattainable with the single component removal, and can mitigate issues of noise pollution. However, complete exhaust systems generally entail a higher initial cost compared to the more minimal approach.

In conclusion, alternative exhaust options represent a more refined approach to achieving the desired auditory and performance characteristics than simply removing a component on the E90 335i. While the lower cost and perceived simplicity of the component removal may be attractive, the inherent risks related to noise levels, performance unpredictability, and potential regulatory non-compliance should be carefully weighed against the benefits of a comprehensive, engineered system. Ultimately, the decision depends on individual priorities, budget considerations, and a thorough understanding of the relevant technical and legal factors.

Frequently Asked Questions

This section addresses common inquiries and misconceptions surrounding the modification of the E90 335i exhaust system through the removal of the rear sound dampening component.

Question 1: Will the modification lead to a significant horsepower increase?

The removal of the rear sound dampening component typically yields minimal, if any, measurable horsepower gains on a stock E90 335i. Any perceived increase is often attributable to the enhanced exhaust sound and placebo effect, rather than a substantial improvement in engine output. Dyno testing is recommended for objective assessment.

Question 2: Is this modification legal in all jurisdictions?

Legality varies significantly depending on local, state, and federal regulations. Many jurisdictions have noise ordinances that prohibit excessively loud vehicles. Modifying an exhaust system may violate these regulations, resulting in fines or requirements to restore the vehicle to its original configuration. Thorough research of local laws is essential.

Question 3: Does the removal affect the vehicle’s emissions?

The rear sound dampening component is not directly related to emissions control. However, if the modification compromises the function of other emissions-related components, such as catalytic converters, it could lead to emissions violations and failure to pass emissions inspections.

Question 4: Will removing the component cause increased drone or resonance?

Removing the rear sound dampening component often results in increased drone or resonance, particularly at specific engine speeds. This can be undesirable for some drivers, especially during highway cruising. Mitigation strategies include adding resonators or strategically placed sound-deadening materials.

Question 5: Is specialized welding required for the installation process?

If replacement piping is installed, welding is typically required to ensure a secure and leak-free connection. Proper welding techniques are essential to prevent exhaust leaks, which can degrade performance and safety. Professional installation is recommended for those without welding experience.

Question 6: Are there alternative exhaust modifications that offer similar benefits with fewer drawbacks?

Commercially available complete exhaust systems offer a more controlled and refined alternative. These systems are engineered to provide a specific sound profile, optimize exhaust flow, and comply with noise regulations. While more expensive, they often provide a more predictable and desirable outcome.

In summary, while the removal of the rear sound dampening component may seem like a straightforward modification, it is essential to consider the legal, performance, and acoustic implications. Thorough research and careful planning are necessary to ensure a satisfactory outcome.

The subsequent section will provide a comprehensive conclusion, summarizing the critical aspects of the “e90 335i muffler delete” modification and offering a final recommendation.

Conclusion

The exploration of the E90 335i muffler delete modification reveals a multifaceted issue with implications extending beyond mere sound enhancement. This modification, intended to alter exhaust acoustics and potentially improve performance, necessitates a careful consideration of legal ramifications, performance expectations, and installation requirements. The analysis demonstrates that while the modification offers a more aggressive exhaust note, the measurable performance gains are typically minimal, and the potential for increased drone or resonance is significant. Moreover, compliance with local noise ordinances and the complexity of achieving a proper, leak-free installation demand a measured approach.

Ultimately, the decision to proceed with this modification should be predicated on a comprehensive understanding of its potential drawbacks and a commitment to responsible execution. Adherence to legal regulations and thoughtful consideration of community impact are paramount. Alternative, commercially available exhaust systems offer a more engineered and predictable path for achieving desired sound and performance characteristics. Therefore, prospective modifiers are encouraged to thoroughly research all available options and weigh the potential benefits against the inherent risks before undertaking any alteration to the vehicle’s exhaust system.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)