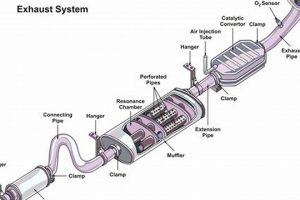

Removing the exhaust component designed to reduce noise involves detaching it from the exhaust system, typically by cutting and welding in a straight pipe section. This modification alters the vehicle’s exhaust note and flow characteristics. Specific procedures depend heavily on the vehicle’s make, model, and year.

The popularity of this alteration stems from perceived enhancements in exhaust flow, potentially leading to minor increases in horsepower, along with a desire for a louder, more aggressive exhaust sound. Historically, such modifications were common among enthusiasts seeking to personalize their vehicles and enhance their performance feel. However, it’s crucial to consider local noise regulations and potential impacts on emissions compliance.

Subsequent sections will detail the potential ramifications of this action, provide a step-by-step overview of the process (disclaimer: not intended as a guide, but to inform), and discuss essential safety considerations. It is imperative to acknowledge that modifying a vehicle’s exhaust system may have legal and environmental consequences.

Essential Considerations Before Undertaking Exhaust System Modification

The following points highlight key considerations before performing any alterations to the exhaust system. Prudence and diligent research are strongly advised.

Tip 1: Verify Local Regulations: Thoroughly investigate noise ordinances and emissions laws in the area. Many jurisdictions have strict regulations regarding vehicle modifications and noise levels. Non-compliance can lead to fines or mandated vehicle repairs.

Tip 2: Assess Potential Performance Impact: While a louder exhaust note might be desirable, a proper evaluation of potential performance gains or losses is vital. The engine management system may require recalibration to optimize performance after modifying the exhaust flow.

Tip 3: Evaluate Welding Proficiency: A secure and leak-free weld is crucial for exhaust system integrity. If welding skills are insufficient, consider engaging a qualified professional for this task. Poor welding can lead to exhaust leaks, compromising performance and potentially introducing harmful fumes into the vehicle’s cabin.

Tip 4: Proper Pipe Selection is Important: Choosing the correct diameter and material for the replacement pipe is key to a well done muffler alteration. Using pipe with a significantly different diameter from the existing exhaust can negatively affect performance. Stainless steel offers superior corrosion resistance compared to aluminized steel.

Tip 5: Employ Correct Safety Measures: Wear appropriate personal protective equipment, including safety glasses, gloves, and a welding helmet, when working on the exhaust system. Ensure the work area is well-ventilated to avoid inhaling harmful fumes. Allow the exhaust system to cool completely before commencing work to prevent burns.

Tip 6: Maintain Original Components: If planning to revert to the original configuration, retain the original muffler and associated hardware. This facilitates a simpler restoration process.

Consideration of these points will mitigate potential legal issues, ensure structural integrity, and promote safety throughout the modification process. Performing proper research can save time, money, and stress.

The concluding section of this article will discuss potential alternatives to total removal, offering quieter yet still performance-oriented options.

1. Regulations and compliance

The act of removing a muffler invariably intersects with established noise and emissions regulations, creating potential legal ramifications. Most jurisdictions enforce noise ordinances restricting vehicle sound levels, often measured in decibels. A muffler significantly attenuates exhaust noise, and its removal generally leads to a violation of these standards. For example, many states implement roadside noise testing, where vehicles exceeding the limit are subject to fines and required corrective action. Furthermore, altering the exhaust system can affect emissions control equipment, possibly resulting in non-compliance with emissions standards. Tampering with catalytic converters or other emission-related components can trigger “check engine” lights and fail emissions inspections, rendering the vehicle illegal for road use.

The importance of regulatory compliance in the context of exhaust modifications extends beyond immediate legal penalties. Repeated offenses can lead to increased fines, vehicle impoundment, and even legal action. Moreover, non-compliance can impact vehicle insurance coverage. An insurance company may deny claims if it determines that the vehicle was illegally modified and that the modification contributed to the incident. From an environmental perspective, removing or altering emissions control devices contributes to air pollution, potentially affecting public health and environmental quality. A vehicle failing to meet emissions standards emits higher levels of pollutants, such as carbon monoxide and nitrogen oxides, which contribute to smog and respiratory problems.

In summary, regulations and compliance are crucial components of this topic. It is an essential decision-making element. Disregarding these factors can have substantial legal, financial, and environmental repercussions. Before undertaking any modification, it is imperative to research and understand local regulations and assess the potential impact on vehicle emissions and noise levels. In many situations, exploring alternatives that enhance performance and sound without violating regulations is the more responsible approach.

2. Exhaust Flow Dynamics

Exhaust flow dynamics represent a critical consideration when contemplating muffler alterations. Understanding how exhaust gases behave within the system is essential for predicting the impact of modification on engine performance and overall efficiency.

- Backpressure Influence

Backpressure refers to the resistance exhaust gases encounter as they exit the engine. A properly designed muffler creates a specific level of backpressure optimized for engine performance. Removing the muffler alters this backpressure, potentially reducing low-end torque. For example, a vehicle designed with a certain backpressure requirement may experience a decrease in responsiveness at lower RPMs after this action due to reduced scavenging efficiency.

- Velocity and Scavenging

Exhaust gas velocity plays a crucial role in scavenging, the process of drawing out exhaust gases and creating a vacuum to aid in cylinder filling. A muffler helps maintain exhaust velocity; eliminating it can disrupt this balance. For instance, if the exhaust flow becomes too unrestricted, it may hinder the engine’s ability to efficiently remove spent gases from the combustion chamber, leading to reduced horsepower.

- Resonance and Wave Propagation

Exhaust systems are designed to manage sound waves produced by the engine. Mufflers utilize chambers and baffles to cancel out specific frequencies, resulting in quieter operation. Removing this component disrupts these wave propagation patterns. Consequently, sound waves resonate differently, potentially creating undesirable droning or excessive noise levels. A vehicle with a modified system lacking proper resonance tuning might experience increased cabin noise at certain speeds.

- Impact on Turbocharging

In turbocharged vehicles, exhaust flow dynamics are even more critical. The turbine wheel is driven by exhaust gases, and any alteration affecting flow can significantly impact turbocharger performance. A poorly executed modification can lead to turbo lag or over-spooling. For instance, if the exhaust flows too freely, the turbocharger may not build boost as quickly at lower RPMs. Conversely, if the flow is insufficient, it may over-spool at high RPMs, potentially damaging the turbocharger.

These facets illustrate the complexities of exhaust flow dynamics and its relevance to muffler alterations. Simply removing this component without considering these factors can yield unexpected results, potentially negatively impacting performance, sound quality, and even engine longevity. Thorough research and consideration of the entire exhaust system are essential for achieving the desired outcome without compromising vehicle functionality.

3. Welding Quality Imperative

The integrity of any exhaust system modification, particularly in instances of muffler removal and replacement with a straight pipe section, hinges critically on the quality of the welding. Inadequate welding results in leaks, compromising exhaust flow, reducing performance, and introducing the potential for dangerous exhaust fumes to enter the vehicle’s cabin. A poorly executed weld is susceptible to cracking and failure under the extreme heat and vibration present in an exhaust system. For example, a pinhole leak, initially small, can rapidly expand due to thermal stress, negating any intended performance gains and creating a safety hazard. Moreover, weak welds necessitate repeated repairs, increasing the overall cost and labor involved. A straight pipe replacement, however well-intentioned, is rendered ineffective and potentially detrimental if the weld joints connecting it to the existing exhaust are compromised. The welding must ensure a complete, air-tight seal, capable of withstanding the rigors of daily driving and temperature fluctuations.

The welding process requires a skilled operator, appropriate equipment, and the correct welding technique for the specific materials being joined. Different types of steel, such as mild steel and stainless steel, necessitate different welding processes and filler materials. Using an inappropriate technique or filler can result in a weak or corroded weld. The surface preparation prior to welding is also paramount. Removing rust, paint, and other contaminants ensures proper adhesion and fusion of the weld metal. A seemingly minor oversight in surface preparation can dramatically reduce weld strength and longevity. The geometric configuration of the weld joint also contributes to its strength and resistance to stress. Overlapping welds and proper penetration of the weld metal into the base metal are essential for a robust and durable connection.

In conclusion, the quality of the welding is not merely a procedural detail but a fundamental determinant of the success, safety, and longevity of exhaust system modifications, specifically a muffler removal procedure. From initial performance gains to long-term structural integrity, the weld quality dictates the overall outcome. The cost and effort involved in obtaining a high-quality weld are a necessary investment in the reliability and safety of the vehicle. A weld is only as strong as its weakest point, and a failure in this area can have cascading negative consequences. Consequently, engaging a qualified professional with demonstrated expertise in exhaust system welding is strongly recommended, ensuring a secure, leak-free, and durable connection.

4. Pipe material selection

The selection of appropriate pipe material is critical when removing a muffler and replacing it with a straight pipe section. The chosen material directly impacts the exhaust system’s durability, performance, and longevity.

- Mild Steel Characteristics

Mild steel, a common and economical option, offers adequate strength for exhaust systems. However, it is susceptible to corrosion, particularly in regions with high humidity or road salt usage. For example, a mild steel replacement pipe in a northern climate may exhibit rust within a year, eventually leading to leaks and requiring replacement. This contrasts sharply with more corrosion-resistant materials.

- Stainless Steel Advantages

Stainless steel presents a superior alternative due to its enhanced corrosion resistance. The chromium content forms a protective layer, preventing rust even in harsh conditions. A stainless steel pipe, while more expensive initially, will typically outlast a mild steel counterpart by several years. For example, a stainless steel system may remain structurally sound for a decade or more, providing a cost-effective solution over the long term.

- Aluminized Steel Considerations

Aluminized steel offers a compromise between mild steel and stainless steel. A coating of aluminum provides some corrosion protection, extending its lifespan compared to mild steel. However, the aluminum layer is susceptible to damage from physical impacts or abrasion, exposing the underlying steel to corrosion. An aluminized pipe used in off-road applications may suffer damage to the coating, negating its protective benefits.

- Diameter and Gauge Influence

Beyond the base material, the pipe’s diameter and gauge (thickness) also impact performance and durability. A larger diameter may reduce backpressure, potentially increasing horsepower, but can also decrease exhaust velocity at lower RPMs. A thicker gauge provides greater resistance to dents and deformation, particularly important in off-road vehicles or those subjected to harsh conditions. Selecting the appropriate diameter and gauge requires careful consideration of the vehicle’s engine characteristics and intended usage.

These considerations regarding pipe material underscore their significance in modifying an exhaust system. The choice of material should align with the vehicle’s operating environment, performance goals, and budget constraints. Careful selection contributes to a durable, reliable, and optimized exhaust system following muffler removal.

5. Safety protocol adherence

Adhering to stringent safety protocols is paramount when undertaking exhaust system modifications, especially during a muffler removal procedure. The inherent risks associated with cutting, welding, and working under a vehicle necessitate strict adherence to established safety guidelines.

- Eye Protection Imperative

The use of appropriate eye protection, specifically safety glasses or a face shield, is mandatory to shield against flying debris, sparks, and metal fragments generated during cutting and grinding operations. Failure to wear eye protection can result in severe eye injury, including permanent vision impairment. For example, grinding metal can project small, hot particles at high velocity, easily penetrating unprotected eyes.

- Respiratory Protection Necessity

Welding produces fumes containing hazardous substances, including metal oxides and gases. Prolonged inhalation can cause respiratory irritation, metal fume fever, and long-term health problems. A properly fitted respirator, designed to filter out these contaminants, is essential. A simple dust mask is insufficient. For instance, welding galvanized steel releases zinc oxide fumes, known to cause metal fume fever, characterized by flu-like symptoms.

- Thermal Protection Mandate

Exhaust systems operate at extremely high temperatures, posing a significant burn risk. Allowing the exhaust system to cool completely before commencing work is crucial. Furthermore, wearing heat-resistant gloves protects hands from burns when handling hot metal surfaces. Contact with a hot exhaust component can cause severe burns requiring medical attention, emphasizing the importance of thermal protection.

- Vehicle Support and Stability

Working under a vehicle requires secure and stable support. Using jack stands rated for the vehicle’s weight is imperative. Relying solely on a hydraulic jack is inherently unsafe, as jacks can fail, causing the vehicle to collapse. For example, if a jack fails while someone is underneath, the resulting crush injury can be fatal. Proper placement of jack stands on designated support points is equally important to ensure stability.

Ignoring these fundamental safety protocols while undertaking an exhaust modification, particularly a muffler deletion, elevates the risk of serious injury or death. These procedures, if not followed diligently, transform what is often perceived as a simple automotive task into a potentially life-threatening situation. Prioritizing safety is not optional but integral to the responsible execution of any vehicle modification.

Frequently Asked Questions

The following addresses common inquiries and concerns regarding exhaust system modifications, specifically the act of removing a muffler. This information is provided for informational purposes and does not constitute an endorsement of the practice.

Question 1: Is removing a muffler legal?

Legality is jurisdiction-dependent. Many regions have noise ordinances that this modification may violate. Local laws must be checked before undertaking such actions.

Question 2: Will removing a muffler increase horsepower?

Marginal power gains are possible, but not guaranteed. Engine design and exhaust system characteristics dictate any performance change. Re-calibration of the engine management system may be needed to realize any gains.

Question 3: Does this modification affect fuel economy?

Fuel economy may be negligibly affected. Altered exhaust flow can influence engine efficiency, but the impact is generally minimal unless accompanied by other modifications and a corresponding engine tune.

Question 4: Will muffler deletion damage the engine?

Direct engine damage is unlikely if performed correctly. However, improper exhaust flow can, over time, negatively influence engine performance and longevity. Maintaining adequate backpressure is essential.

Question 5: Can a muffler be reinstalled after removal?

Reinstallation is possible, but requires reversing the removal process. The original muffler and connecting hardware should be retained to facilitate restoration to the factory configuration.

Question 6: What are the alternative modifications?

Performance mufflers offer an alternative. They increase exhaust flow and sound output while maintaining a degree of noise reduction, potentially satisfying regulatory requirements. High-flow catalytic converters and resonator modifications are also options.

This FAQ underscores that muffler removal is a multifaceted decision involving legal, performance, and environmental factors. Careful consideration of these elements is crucial before proceeding.

The next section will explore alternatives that provide increased sound or performance with less risk.

Concluding Remarks on Muffler Deletion

This exploration has elucidated the key facets of the action, encompassing legal ramifications, performance implications, safety protocols, and material considerations. The multifaceted nature of the operation demands diligent research and a comprehensive understanding of its potential consequences. The presented information has sought to provide an objective overview, outlining both potential benefits and inherent risks. Modification of an exhaust system involves more than simply removing a component; it entails altering complex interactions within the vehicle’s engine and emissions control systems.

Ultimately, the decision to proceed with this act rests with the individual. However, prudence dictates a thorough evaluation of all factors, weighing potential gains against potential liabilities. Responsible vehicle modification considers not only personal preferences but also legal compliance, environmental impact, and long-term vehicle health. Before undertaking any modifications, consultation with qualified professionals is strongly encouraged, ensuring that any actions align with both personal goals and responsible vehicle ownership. The environmental and societal impact of unregulated vehicle modification is a serious concern.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)