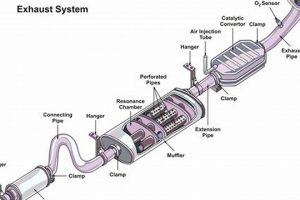

A modification involving the removal of a vehicle’s muffler, while circumventing the need for welding, typically relies on methods like using clamps, flanges, or specialized exhaust connectors. These approaches allow for a direct replacement of the muffler with a straight pipe or a similar component, facilitating a change in the vehicle’s exhaust sound and potentially its performance characteristics. The process aims to achieve the desired outcome without permanent attachment methods.

This type of modification is often pursued to alter a vehicle’s sound profile, making it louder and more aggressive. Some individuals may also believe it improves exhaust flow, leading to a slight increase in horsepower. Historically, such modifications were more common due to simpler vehicle designs and fewer emissions regulations. However, it is important to be aware that the legality and impact on emissions compliance can vary significantly depending on local laws and regulations.

The following sections will delve into the tools, materials, and procedural steps involved in performing this type of exhaust system modification. It will also cover potential drawbacks, legal considerations, and best practices for ensuring a safe and effective outcome.

Tips for Muffler Removal Without Welding

Executing an exhaust modification without welding requires meticulous planning and attention to detail. The following tips offer guidance on ensuring a successful and safe outcome.

Tip 1: Accurate Measurements: Prior to commencing, precise measurements of the existing exhaust system are essential. This ensures the replacement pipe or component has the correct length and diameter for a secure fit. Discrepancies in measurement can lead to leaks and improper installation.

Tip 2: Utilize Quality Clamps: Invest in high-quality exhaust clamps designed for secure and leak-proof connections. Stainless steel clamps are preferred for their durability and resistance to corrosion, ensuring longevity of the connection.

Tip 3: Consider Flange Adapters: If the existing exhaust system uses flanges, explore using flange adapters. These provide a direct bolt-on solution, eliminating the need for welding and simplifying the installation process. Verify proper flange size and bolt pattern compatibility.

Tip 4: Apply Exhaust Sealant: To further mitigate the risk of exhaust leaks, apply a high-temperature exhaust sealant to all connection points before tightening clamps or bolts. This creates a tighter seal and helps to prevent exhaust gases from escaping.

Tip 5: Secure Hangers: Ensure that the replacement pipe or component is adequately supported by utilizing existing exhaust hangers or installing new ones if necessary. Proper support prevents stress on the connections and minimizes the risk of damage from vibrations.

Tip 6: Double-Check Connections: After installation, meticulously inspect all connections for tightness and proper alignment. A thorough inspection helps to identify any potential leaks or issues before operating the vehicle.

Tip 7: Acoustic Considerations: Bear in mind that altering the exhaust system will significantly affect the vehicle’s sound. Consider the desired sound level and potential noise ordinances in the area. Research sound-dampening options if a quieter result is preferred.

Adhering to these tips will help ensure a secure, reliable, and legally compliant exhaust modification. Thorough preparation and careful execution are key to a successful project.

The next section will address potential problems and offer troubleshooting advice related to exhaust modifications.

1. Measurements

Precise dimensional assessment forms the foundational step in executing an exhaust modification without welding. The accuracy of these measurements directly impacts the success and integrity of the modification, influencing component selection and overall system functionality.

- Pipe Diameter Compatibility

Determining the exact outer diameter of the existing exhaust piping is crucial. Incompatible diameters prevent proper clamping or connection. For example, if the existing pipe measures 2.5 inches, the replacement pipe or adapter must also be 2.5 inches to ensure a secure and leak-free fit.

- Muffler Length and Offset

The original muffler’s length and offset determine the required length and configuration of the replacement pipe. If the replacement pipe is too short, it can create excessive strain on the remaining exhaust system. Conversely, if it’s too long, it may interfere with other vehicle components or require additional cutting and adjustment. Consider the muffler’s inlet and outlet locations relative to the chassis.

- Hanger Placement

Measurements related to the location of existing exhaust hangers are essential for maintaining proper support of the modified exhaust system. Failure to accurately replicate hanger positions can lead to excessive vibration, stress fractures in the pipes, and potential damage to the vehicle’s undercarriage. Account for both the vertical and horizontal positioning of the hangers.

- Clearance Considerations

Assessing available space around the exhaust system ensures that the modified system doesn’t interfere with other vehicle components such as the fuel tank, suspension components, or underbody panels. Inadequate clearance can result in rattling, heat damage, or even physical interference that impairs vehicle operation. Measurements should account for dynamic movement of the chassis under load.

These dimensional assessments, when meticulously conducted, directly facilitate the execution of the muffler removal without welding. Accurate measurements minimize the need for on-the-fly adjustments and guarantee a structurally sound and properly aligned exhaust modification. Failure to prioritize precise measurements can lead to complications, compromises in system integrity, and potential damage to associated vehicle components.

2. Clamping

In the context of exhaust system modification, specifically in circumstances where welding is not employed, clamping serves as a critical methodology for securing connections between exhaust components. The effectiveness of clamping mechanisms directly influences the structural integrity and gas-tightness of the modified exhaust system.

- Clamp Selection and Material Composition

The choice of clamp type and material is paramount. Common types include U-bolt clamps, band clamps, and saddle clamps. Material selection, such as stainless steel, dictates resistance to corrosion and longevity of the connection. A mismatch in clamp type or inferior material can lead to premature failure and exhaust leaks. Stainless steel band clamps, offering uniform pressure distribution, are often favored for their robustness in high-temperature environments.

- Torque Specifications and Installation Procedure

Adhering to specified torque values during clamp installation is essential to achieve optimal clamping force without damaging the exhaust pipes. Over-tightening can deform the pipes, while under-tightening results in insufficient sealing. A calibrated torque wrench should be used. The installation procedure typically involves positioning the clamp over the joint, ensuring proper alignment, and gradually tightening the clamp fasteners to the specified torque.

- Leak Prevention Strategies

Effective clamping contributes significantly to leak prevention. Exhaust leaks not only reduce engine performance but also pose potential safety hazards due to carbon monoxide exposure. The application of exhaust sealant at the joint prior to clamping can enhance the seal. Regular inspection of clamps for corrosion or loosening is crucial for maintaining a leak-free system.

- Compatibility with Pipe Dimensions and Configurations

Selecting clamps that are appropriately sized for the exhaust pipe dimensions is fundamental. Clamps that are too small will not fit, while those that are too large will not provide adequate clamping force. The clamp configuration must also be compatible with the exhaust pipe configuration. For instance, some clamps are designed for use with slip-fit connections, while others are intended for flanged connections.

The proper selection, installation, and maintenance of clamping mechanisms are indispensable for achieving a reliable and safe exhaust modification when welding is not employed. The failure of clamping components can compromise the structural integrity of the exhaust system, leading to performance degradation and potential safety concerns. Therefore, meticulous attention must be given to clamping techniques to ensure a successful and enduring exhaust system modification.

3. Connectors

In exhaust system modification, particularly when circumventing welding, connectors become indispensable components. Their presence dictates the ease, security, and longevity of the resulting assembly. Circumventing welding when implementing a muffler removal places increased emphasis on the quality and compatibility of connectors. These serve to bridge the gap left by the removed muffler, joining the remaining exhaust piping. A common example involves using band clamps with pre-fabricated pipes that have flared ends for a secure, leak-proof fit. The correct connector type, such as a flange adapter, will eliminate the need for specialized tools and the complexities of welding. Choosing the right connector is thus critical for the success of the modification.

Several connector types address varied exhaust configurations. Slip-fit connectors, secured with clamps, allow for adjustability. Flanged connectors, using bolts and gaskets, provide a more rigid and potentially leak-resistant connection. Ball-and-socket connectors accommodate slight misalignments. The selection depends upon the existing exhaust system’s design and the desired level of adjustability. Incorrect connector selection can lead to exhaust leaks, improper fitment, and potential damage to other vehicle components due to stress and vibration. Practical application requires a thorough assessment of the original exhaust setup.

Connectors are integral to enabling muffler removal without welding. They offer a means to achieve a modified exhaust configuration, but necessitate careful consideration of their type, material, and installation. The long-term performance and safety of the exhaust modification depend significantly on the quality and appropriate application of these connectors. Challenges may arise in ensuring a completely leak-free seal, but proper installation techniques and selection of high-quality components mitigate these risks.

4. Alignment

Proper alignment is a critical factor in the successful execution of a muffler removal, especially when welding is not utilized as the primary joining method. Misalignment between exhaust components introduces stress points, creating potential leak paths and compromising the structural integrity of the exhaust system. When clamps, flanges, or other mechanical connectors are used, any pre-existing stress from misalignment can lead to premature failure of these connectors or deformation of the exhaust piping itself. For instance, if the replacement pipe section is not aligned correctly with the existing exhaust, the clamps will be under uneven pressure, leading to loosening and leaks over time. This highlights the cause-and-effect relationship where initial misalignment results in subsequent performance issues.

The importance of correct alignment is further underscored when considering the long-term effects of vibration and thermal expansion inherent in exhaust systems. A misaligned system is more susceptible to amplified vibrations, which can accelerate wear and tear on connectors and hangers. Similarly, uneven thermal expansion due to misalignment can cause further stress and warping of the exhaust pipes. As a practical example, consider a vehicle with a slightly bent exhaust pipe before the muffler removal. If the replacement pipe is connected without addressing this pre-existing bend, the added stress from the bend can lead to a crack near the connecting point, requiring costly repairs. Thoroughly checking and correcting alignment issues before installation greatly improves the longevity and reliability of the modified exhaust.

In summary, alignment is not merely a cosmetic concern but a fundamental requirement for a functional and durable exhaust modification. Neglecting alignment can negate the advantages of a non-welded approach, leading to frequent maintenance, noise issues, and potential safety hazards. By prioritizing accurate alignment during the muffler removal and replacement process, the effectiveness and lifespan of the modification are significantly enhanced, contributing to overall vehicle performance and safety. Achieving appropriate alignment is crucial to mitigate premature component failure.

5. Sealant

Sealant plays a vital role in exhaust system modifications, particularly when a muffler removal is performed without welding. Its application aims to create a gas-tight barrier at connection points, mitigating leaks and ensuring efficient exhaust flow, thereby sustaining optimal engine performance.

- High-Temperature Resistance

Exhaust systems experience extreme temperature fluctuations. Sealants designed for exhaust applications possess high-temperature resistance to maintain their integrity under these conditions. Standard sealants may degrade and fail, leading to leaks. An example is a silicone-based sealant specifically formulated to withstand temperatures exceeding 500 degrees Fahrenheit, which is applied to flange connections in the absence of a proper weld.

- Leak Prevention

Exhaust leaks diminish engine efficiency, increase noise levels, and pose potential safety hazards due to carbon monoxide emissions. Sealant effectively fills minor imperfections between connecting surfaces, creating a seal that prevents the escape of exhaust gases. When installing a slip-fit adapter after removing a muffler, a bead of sealant applied to the joint before clamping provides a barrier against leaks that might otherwise occur due to imperfect pipe alignment.

- Corrosion Inhibition

Exhaust systems are exposed to corrosive elements, including moisture and road salts. Some sealants contain corrosion inhibitors that protect metal surfaces from degradation. These inhibitors form a protective layer that extends the lifespan of the exhaust components and maintains the integrity of the connections. An example involves applying sealant to the outer surface of clamped joints to prevent rust formation at the contact points between the clamp and the exhaust pipe.

- Application Techniques

Proper sealant application is essential for achieving optimal results. Surfaces must be clean and free of debris before sealant is applied. The sealant should be applied evenly and in sufficient quantity to fill any gaps. Over-application can lead to excess sealant squeezing out, potentially obstructing exhaust flow. A thin, continuous bead of sealant applied around the circumference of a pipe joint, followed by immediate connection and clamping, exemplifies proper application technique.

Therefore, the selection and application of sealant are critical when executing a muffler removal without welding. Its proper use contributes significantly to the overall performance, safety, and longevity of the modified exhaust system. Sealant ensures a secure and airtight connection, essential for maintaining engine efficiency and preventing potential hazards.

6. Regulations

Regulations exert a considerable influence on the legality and practical execution of exhaust system modifications, specifically impacting the action of muffler removal without welding. The consequences of non-compliance with these regulations may range from fines and vehicle inspection failures to legal sanctions. Noise ordinances are a primary concern, as many jurisdictions have established decibel limits for vehicle exhaust. A muffler removal typically elevates exhaust noise, potentially exceeding these limits, resulting in legal penalties. Moreover, regulations concerning vehicle emissions may prohibit modifications that tamper with or remove emissions control devices, a category that some interpretations extend to include mufflers. Therefore, understanding and adhering to applicable regulations is a fundamental aspect of executing this modification.

Real-world instances highlight the importance of considering regulations. For example, in California, modifications that alter or remove original emissions control equipment are prohibited, as enforced by the California Air Resources Board (CARB). Performing a muffler removal could lead to a failed smog check, preventing vehicle registration. In contrast, some rural areas may have less stringent enforcement of noise regulations, yet still maintain requirements for exhaust systems to be “in good working order,” a vague standard that could be subject to interpretation. The practical significance of understanding these nuances is that it allows individuals to make informed decisions about modifications, weighing the potential benefits against the risk of legal repercussions. Failure to do so can result in unexpected fines or the requirement to restore the exhaust system to its original configuration.

In conclusion, the connection between regulations and the act of muffler removal without welding is undeniable. Compliance with local and national laws is an indispensable component of any modification endeavor. Understanding and adhering to legal requirements, coupled with careful consideration of the potential impact on noise and emissions, promotes responsible vehicle modification practices. Navigating the complexity of automotive regulations is crucial for ensuring both the legality and the long-term viability of any exhaust system alteration.

Frequently Asked Questions

This section addresses common inquiries regarding the process of removing a vehicle’s muffler without employing welding techniques.

Question 1: Is muffler removal without welding a reversible modification?

The reversibility depends largely on the methods used for the replacement. If clamps and pre-fabricated pipes are used, the process is typically reversible, provided the original muffler and any removed sections of piping are retained. If cutting of the original exhaust is involved, restoration to the original configuration becomes more complex and may necessitate welding.

Question 2: What tools are generally required for this type of modification?

The typical toolset includes, but is not limited to, a socket set, wrenches (of appropriate sizes for exhaust clamps), a pipe cutter or saw (if cutting is necessary), a torque wrench, safety glasses, and potentially penetrating oil to aid in disassembling rusted components.

Question 3: How can exhaust leaks be prevented when removing a muffler without welding?

The use of high-quality exhaust clamps, careful alignment of components, and the application of high-temperature exhaust sealant at connection points are crucial for preventing leaks. Thorough inspection of all connections after installation is also recommended.

Question 4: What potential performance changes can be expected?

Performance effects are often minimal or negligible. While some may perceive a slight increase in horsepower due to reduced backpressure, this is often outweighed by potential losses in low-end torque. The primary and most noticeable change is typically an increase in exhaust noise.

Question 5: Does a muffler removal impact fuel economy?

Any impact on fuel economy is usually minimal and potentially unnoticeable. Changes in driving habits, induced by the altered exhaust sound, may have a more significant effect on fuel consumption than the modification itself.

Question 6: What are the legal ramifications of removing a muffler?

Legality varies significantly by jurisdiction. Many regions have noise ordinances that prohibit excessively loud exhaust systems. Additionally, regulations concerning emissions control may restrict modifications that remove or alter original equipment. Prior to undertaking this modification, it is imperative to consult local laws and regulations.

These FAQs offer fundamental information to guide informed decisions related to muffler removal without welding. Diligence in researching regulations and employing sound installation practices are paramount.

The subsequent section will provide a concluding overview of the key considerations.

Conclusion

This exposition has explored the facets of a specific exhaust modification: muffler removal without welding. It has addressed techniques for secure connections absent welding, emphasized the importance of accurate measurements and component compatibility, and underscored the necessity of adhering to legal and regulatory standards. Proper planning, connector and clamp selection, and accurate sealant application are critical to the modification’s success.

Modifying a vehicle’s exhaust system necessitates careful consideration of both performance aspirations and potential legal ramifications. Individuals contemplating such alterations are encouraged to prioritize thorough research, meticulous execution, and adherence to local regulations to ensure a safe, compliant, and ultimately satisfactory outcome. The long-term consequences of modifications should be weighed against short-term benefits, acknowledging that responsible vehicle stewardship encompasses both performance and legal compliance.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)