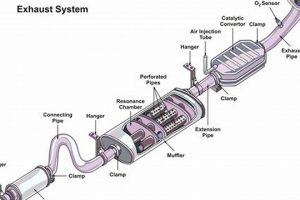

The removal of the initial silencing component in the exhaust system of a Volvo 240, typically located after the catalytic converter, is a modification commonly undertaken to alter the vehicle’s sound characteristics. This alteration often results in a louder and potentially more aggressive exhaust note. The procedure involves detaching the specified component and replacing it with a straight pipe or a similar connecting piece.

Performing this modification can lead to a perceived increase in horsepower, although this is generally minimal on a naturally aspirated engine such as those commonly found in the Volvo 240. A primary motivation is often to achieve a more pronounced engine sound. Historically, modifications like this were more prevalent due to fewer emission regulations; contemporary applications are often driven by personal preference for sound and aesthetics.

The following sections will delve into the potential ramifications of such a modification, including its impact on vehicle performance, sound levels, legal compliance, and potential alternatives for those seeking similar results without the complete removal of factory components.

Essential Considerations

The following points are crucial for those considering exhaust modifications to a Volvo 240.

Tip 1: Legal Compliance: Prior to any modification, thoroughly research local noise ordinances and emission standards. Removal of exhaust components can result in non-compliance, leading to fines or failed inspections. Verify that alterations meet all applicable regulations.

Tip 2: Assess Sound Level Tolerance: Before committing to a complete removal, consider the potential increase in exhaust volume. Drive or listen to examples of similarly modified vehicles to determine if the increased sound is acceptable for daily driving and neighborhood considerations.

Tip 3: Consider Alternatives: Explore options such as performance mufflers or resonators. These components can provide a modified exhaust note without the drastic increase in volume associated with component removal, and can help maintain some level of noise reduction.

Tip 4: Professional Installation: Engaging a qualified mechanic is highly recommended for any exhaust modification. Proper welding, fitment, and sealing are critical to ensure optimal performance and prevent exhaust leaks.

Tip 5: Evaluate Performance Impact: Understand that removing an exhaust component may not significantly increase horsepower, particularly on a stock engine. The primary benefit is typically a change in exhaust sound.

Tip 6: Documentation: Keep detailed records of all modifications performed, including receipts and any inspections conducted. This documentation can be valuable for future maintenance or resale purposes.

Tip 7: Material Selection: If fabricating a replacement pipe, use materials of comparable quality to the original exhaust system. Stainless steel offers corrosion resistance and longevity. Ensure compatibility with existing exhaust components.

These tips highlight the importance of careful planning and consideration when altering the exhaust system of a Volvo 240. Adhering to these points can help achieve desired results while minimizing potential drawbacks.

The subsequent sections will address specific performance considerations, noise management techniques, and provide a comparison of common exhaust system components.

1. Sound amplification

Sound amplification is a primary consequence of removing the initial muffler from a Volvo 240’s exhaust system. This modification directly impacts the vehicle’s auditory signature, altering both its perceived character and potential compliance with local noise regulations.

- Increased Decibel Levels

The removal of a muffler directly reduces the exhaust system’s ability to attenuate sound waves. This results in higher decibel levels emitted by the vehicle, particularly during acceleration and high-RPM operation. Measuring the decibel level before and after modification is essential to ensure the vehicle remains within legal limits.

- Frequency Spectrum Modification

Beyond simply increasing volume, component removal alters the frequency spectrum of the exhaust note. It can introduce higher frequencies and more aggressive tones that were previously dampened by the muffler. This change in tonal quality often contributes to the perception of increased performance, even if actual power gains are minimal.

- Resonance and Drone

Sound amplification can also lead to increased resonance within the exhaust system and vehicle cabin. This resonance, often referred to as “drone,” is a low-frequency hum that can be particularly noticeable at certain engine speeds. Mitigating drone often requires the addition of resonators or other sound-dampening components.

- Impact on Noise Regulations

The most critical consideration associated with sound amplification is its potential violation of local noise ordinances. Many jurisdictions have specific decibel limits for vehicle exhaust, and removing the muffler can easily exceed these limits. Non-compliance can result in fines, required repairs, or restrictions on vehicle operation.

In conclusion, while the increased sound amplification resulting from muffler removal on a Volvo 240 may be desirable for some enthusiasts, it is essential to carefully consider the potential negative consequences. These include regulatory violations, increased cabin noise, and potential for irritating frequencies. Thorough research and consideration of alternatives are crucial before undertaking such a modification.

2. Backpressure change

Backpressure change is an inevitable consequence of modifying an exhaust system, and removing the first muffler on a Volvo 240 directly influences this parameter. Backpressure, in this context, refers to the resistance to exhaust flow within the system. Altering this resistance affects engine performance, fuel efficiency, and overall operational characteristics.

- Engine Performance Characteristics

Removing the first muffler generally reduces backpressure. While often perceived as a performance enhancement, this reduction can negatively impact low-end torque, particularly in naturally aspirated engines like those commonly found in Volvo 240 models. The engine may feel less responsive at lower RPMs due to the reduced scavenging effect caused by lower backpressure. This phenomenon occurs because the exhaust pulses no longer effectively draw out the remaining exhaust gases from the cylinder during the overlap period between exhaust and intake valve openings.

- Exhaust Gas Scavenging

Backpressure plays a role in exhaust gas scavenging, the process of effectively removing exhaust gases from the combustion chamber. With reduced backpressure, the scavenging effect can diminish, potentially leading to incomplete combustion and reduced engine efficiency. This can manifest as slightly decreased fuel economy or increased emissions.

- Impact on Turbocharged Engines

In turbocharged applications (less common in factory Volvo 240s but relevant in modified scenarios), the impact of backpressure reduction differs. Turbocharged engines often benefit from reduced backpressure after the turbocharger, as it allows the turbine to spin more freely, improving boost response and potentially increasing overall power output. However, even in these cases, careful consideration must be given to the overall exhaust system design to avoid detrimental effects.

- System Design Considerations

The location of the component removal is crucial. Removing the first muffler, positioned further downstream from the engine, may have a less dramatic impact on backpressure compared to removing the catalytic converter or other upstream components. However, any alteration will influence the exhaust flow dynamics and require consideration of the overall system design to optimize performance and minimize negative consequences.

In summary, the alteration of backpressure resulting from the “volvo 240 first muffler delete” is a multifaceted consideration. While it may offer a perceived improvement in exhaust flow and sound, a thorough understanding of its potential impact on engine performance, fuel efficiency, and exhaust gas scavenging is crucial. Careful evaluation of the specific engine configuration and intended use is necessary to determine the suitability of this modification.

3. Legality assessment

Legality assessment constitutes a critical phase in considering the removal of the first muffler from a Volvo 240. Modifying a vehicle’s exhaust system carries legal implications that vary significantly based on geographical location and jurisdictional regulations. Ignoring these regulations can result in substantial penalties, failed vehicle inspections, and potential restrictions on vehicle usage.

- Noise Ordinances

Municipalities frequently enforce noise ordinances designed to limit excessive sound emissions. These ordinances often stipulate maximum permissible decibel levels for vehicle exhaust. The removal of a muffler, even the first in a series, can readily exceed these limits, particularly in densely populated areas. Enforcement mechanisms may include roadside testing, requiring vehicles exceeding established thresholds to undergo corrective action.

- Emission Standards

Many jurisdictions mandate adherence to specific emission standards designed to control air pollution. While the first muffler’s removal typically does not directly impact catalytic converter function or other primary emission control devices on a Volvo 240, some regulations prohibit any alteration to the factory exhaust system that could potentially increase emissions. Tampering with the exhaust system may lead to failed emission inspections, hindering vehicle registration and operation.

- Vehicle Inspection Requirements

Periodic vehicle inspections, often required for registration renewal, include scrutiny of the exhaust system. Inspectors typically verify the presence and functionality of mandated components, including mufflers. The absence of the original first muffler can result in inspection failure, requiring reinstatement of the factory component or provision of documentation demonstrating compliance with applicable regulations.

- Federal Regulations (Limited Applicability)

While less directly applicable to modifications performed on older vehicles like the Volvo 240, federal regulations governing aftermarket exhaust systems exist. These regulations primarily target newer vehicles and mandate that aftermarket systems must not degrade emissions performance compared to the original equipment. Although not directly enforced on older vehicles, these federal guidelines provide a framework for assessing the legality of exhaust modifications.

In summary, a thorough legality assessment is paramount prior to undertaking the first muffler removal on a Volvo 240. Scrutinizing local noise ordinances, emission standards, and vehicle inspection requirements can mitigate the risk of legal repercussions. Consulting with local authorities or certified vehicle inspectors can provide clarity on applicable regulations, ensuring that any modifications comply with legal mandates and avoid potential penalties or operational restrictions.

4. Resonance potential

The removal of the initial muffler in a Volvo 240 exhaust system directly influences the vehicle’s resonance characteristics. This modification alters the exhaust gas flow, creating the potential for amplified or newly introduced resonant frequencies within the system and, consequently, inside the vehicle cabin. Such resonance manifests as a low-frequency hum or drone, particularly noticeable at specific engine speeds. This phenomenon is a direct result of the altered exhaust system geometry and the absence of the muffler’s sound-dampening properties. As an example, a Volvo 240 operating at 2500-3000 RPM may exhibit a pronounced droning sound following component removal, due to the creation of resonant frequencies within that range. This can lead to driver and passenger discomfort during extended periods of operation.

The resonance potential stemming from this modification is not merely an auditory nuisance; it impacts the overall driving experience and can necessitate further adjustments to the exhaust system. The specific frequency and intensity of the resonance are contingent on factors such as exhaust pipe diameter, length, and the presence of other exhaust components. Mitigating this resonance often requires the introduction of resonatorsspecifically designed components aimed at counteracting unwanted frequencies. These resonators function by creating destructive interference, thereby attenuating the resonant sound waves and reducing the drone experienced within the cabin. Without addressing the resonance, the modification might compromise the vehicle’s usability for daily driving.

Understanding the resonance potential associated with removing the first muffler on a Volvo 240 is crucial for informed decision-making. The anticipated sound characteristics, including the likelihood of drone, should be carefully considered alongside any potential performance gains. Managing resonance through the appropriate selection and installation of resonators is a necessary step in optimizing the overall outcome, ensuring a balance between desired exhaust sound and driver comfort. Failure to address the resonance potential can result in an undesirable driving experience, undermining the intended benefits of the exhaust modification.

5. Material choice

The selection of materials for replacing the initial muffler in a Volvo 240’s exhaust system is a crucial determinant of the modification’s longevity, performance, and acoustic properties. The intended service life, budget constraints, and desired sound characteristics directly influence the optimal material choice.

- Stainless Steel Grades

Stainless steel, particularly grades like 304 or 409, is frequently chosen for exhaust components due to its corrosion resistance and durability. 304 stainless offers superior resistance to rust but is generally more expensive and may exhibit a different tonal quality compared to 409. 409 stainless, while more prone to surface rust, is more affordable and provides adequate service life in many environments. In the context of the modification, using stainless steel ensures the replacement pipe withstands exposure to road salts, moisture, and heat cycling, prolonging its functional lifespan.

- Mild Steel Alternatives

Mild steel represents a more budget-friendly option, but its susceptibility to corrosion necessitates protective coatings or regular maintenance. Mild steel replacement pipes will typically require painting or ceramic coating to prevent rapid degradation, particularly in regions with harsh winters or coastal environments. While initially cost-effective, the reduced lifespan of mild steel may lead to more frequent replacements, offsetting the initial savings.

- Pipe Thickness and Gauge

The thickness or gauge of the material impacts its structural integrity and acoustic properties. Thicker gauge steel offers increased resistance to damage from road debris and reduces the likelihood of vibration-induced cracking. However, thicker materials may also slightly dampen exhaust sound. A balance must be struck between durability and desired sound characteristics when selecting the pipe gauge.

- Welding Compatibility

The chosen material must be compatible with the welding processes used to connect it to the existing exhaust system. Stainless steel typically requires TIG or MIG welding with appropriate filler materials, while mild steel can be welded using simpler MIG welding techniques. Ensuring compatibility avoids potential issues with weld integrity and corrosion at the joints.

Ultimately, the material choice for the “volvo 240 first muffler delete” directly influences the modification’s long-term viability and user satisfaction. Careful consideration of environmental factors, budget limitations, and desired performance characteristics is crucial in selecting a material that balances durability, sound quality, and cost-effectiveness. Consulting with a qualified exhaust specialist can aid in making an informed decision based on individual needs and constraints.

6. Welding quality

Welding quality constitutes a critical factor in the successful execution and long-term durability of a “volvo 240 first muffler delete.” The integrity of the welds directly influences the exhaust system’s ability to withstand thermal stresses, vibrations, and corrosive elements encountered during normal vehicle operation.

- Joint Integrity and Exhaust Leaks

Proper weld penetration and fusion are essential to create gas-tight seals at the joints between the replacement pipe and the existing exhaust system. Poor welding techniques, such as insufficient heat input or inadequate surface preparation, can lead to pinholes, cracks, or incomplete fusion, resulting in exhaust leaks. These leaks diminish exhaust system performance, introduce undesirable noise, and potentially allow harmful exhaust gases to enter the vehicle cabin.

- Material Compatibility and Corrosion Resistance

Welding different metals, such as stainless steel to mild steel, requires careful consideration of material compatibility and the selection of appropriate welding processes and filler metals. Incompatible welding techniques can accelerate galvanic corrosion at the joint, weakening the weld over time. Utilizing the correct filler material and welding parameters mitigates this risk, ensuring the weld joint maintains its structural integrity and corrosion resistance.

- Weld Strength and Vibration Resistance

The Volvo 240, like many vehicles, experiences significant vibration during operation. The welds connecting the replacement pipe must possess sufficient strength to withstand these vibrations without cracking or failing. Proper welding techniques, including multi-pass welds or reinforcement techniques, can increase weld strength and resistance to vibration-induced fatigue.

- Aesthetic Considerations and Professional Finish

While primarily functional, weld quality also contributes to the overall aesthetic appearance of the exhaust modification. Clean, uniform welds indicate a professional installation and reflect attention to detail. Poorly executed welds detract from the overall appearance and may suggest underlying structural deficiencies.

In conclusion, the success of a “volvo 240 first muffler delete” hinges significantly on the quality of the welding performed. Sound welding practices ensure a leak-free, durable, and aesthetically pleasing modification that withstands the rigors of daily driving. Engaging a qualified welder with experience in exhaust system fabrication is essential to achieving optimal results and maximizing the longevity of the modification.

Frequently Asked Questions

The following questions address common inquiries and misconceptions surrounding the removal of the initial muffler in a Volvo 240’s exhaust system. This section aims to provide clear, concise, and technically accurate information to aid in making informed decisions.

Question 1: Does removing the first muffler significantly increase horsepower in a Volvo 240?

Generally, no. The removal of the first muffler typically yields minimal gains in horsepower, particularly on a naturally aspirated Volvo 240 engine. The primary consequence is a change in exhaust sound rather than a substantial increase in power output. Any perceived increase in performance is often attributable to the altered auditory experience.

Question 2: Is it legal to remove the first muffler from a Volvo 240?

The legality varies based on local regulations. Many jurisdictions have noise ordinances that set maximum permissible decibel levels for vehicle exhaust. Removing the muffler may violate these ordinances, leading to fines or inspection failures. A legality assessment is crucial before undertaking this modification.

Question 3: Will removing the first muffler affect fuel economy?

The impact on fuel economy is generally minimal. While alterations to exhaust backpressure can theoretically influence fuel efficiency, the change resulting from the removal of the first muffler is unlikely to produce a significant or readily noticeable difference in fuel consumption under normal driving conditions.

Question 4: What is the best material to use for the replacement pipe?

Stainless steel, particularly 304 or 409 grades, is generally recommended due to its corrosion resistance and durability. While mild steel is a less expensive option, its susceptibility to rust necessitates protective coatings and may result in a shorter lifespan. Material selection should balance budget constraints and desired longevity.

Question 5: How can exhaust drone be minimized after removing the first muffler?

Exhaust drone, a low-frequency hum at certain RPMs, can be mitigated through the installation of resonators. Resonators are designed to cancel out specific frequencies, reducing or eliminating the drone. Careful placement and selection of resonators are essential to achieve optimal results.

Question 6: Is professional installation necessary for this modification?

Professional installation is highly recommended. Proper welding, fitment, and sealing are critical to ensure a leak-free and durable exhaust system. Qualified mechanics possess the expertise and equipment necessary to perform the modification correctly, minimizing the risk of future problems.

In summary, the removal of the first muffler from a Volvo 240 primarily affects exhaust sound. Thorough research, consideration of legal implications, and careful execution are essential for achieving satisfactory results without compromising vehicle performance or violating regulations.

The next section will delve into alternative exhaust modifications for those seeking a balance between enhanced sound and regulatory compliance.

Volvo 240 First Muffler Delete

The removal of the initial muffler in a Volvo 240 exhaust system, as explored, represents a modification primarily impacting auditory characteristics. The analysis underscored potential legal ramifications, resonance implications, and the necessity of material selection and welding expertise. Any alteration necessitates a comprehensive understanding of its effects on backpressure, performance nuances, and noise compliance.

Therefore, pursuing a “volvo 240 first muffler delete” demands meticulous planning, regulatory adherence, and professional execution. Further research into alternative exhaust solutions and nuanced evaluation of vehicle-specific requirements will contribute to a more informed and responsible decision. The ultimate consideration remains balancing desired sound characteristics with legal and practical operational requirements.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)