The selection of an appropriate exhaust component for a modified 6.7 Cummins diesel engine, particularly one with emissions control systems removed, necessitates careful consideration. This component plays a crucial role in managing exhaust noise and backpressure, influencing both the driver’s experience and the engine’s operational characteristics. The ideal choice will offer a balance between sound attenuation and minimal restriction of exhaust flow. An example is choosing a high-flow, baffled unit designed to reduce drone while maintaining adequate performance.

Properly managing exhaust flow and noise is critical when modifying a diesel engine. Eliminating factory emissions equipment can significantly alter exhaust characteristics, often resulting in increased noise levels and potential performance changes. Selecting a suitable exhaust component can mitigate unwanted sound, improve the vehicles overall driveability, and potentially optimize engine efficiency. Historically, advancements in exhaust technology have focused on achieving this delicate balance between performance and noise reduction.

The following sections will delve into key factors to consider when choosing an exhaust component for a modified 6.7 Cummins. Topics to be addressed include types of available options, performance implications, and factors that impact the selection process. This information is intended to provide a clear understanding of how to effectively manage exhaust after modifications have been made.

Guidance on Exhaust Component Selection for Modified 6.7 Cummins Engines

This section provides key considerations for selecting an exhaust component when factory emissions equipment has been removed from a 6.7 Cummins engine. Proper selection is crucial for managing sound, backpressure, and overall performance.

Tip 1: Evaluate Sound Attenuation Needs: Assess the desired level of sound reduction. Factors influencing this include local noise ordinances, personal preference, and intended vehicle use (e.g., daily driving vs. off-road). Options range from relatively loud, free-flowing designs to those offering significant noise suppression.

Tip 2: Prioritize Exhaust Flow: Choose a design that minimizes restriction. Excessive backpressure can negatively impact engine performance and fuel economy. Straight-through designs or those with minimal internal baffling generally offer the best flow characteristics.

Tip 3: Consider Material Quality and Durability: Opt for components constructed from high-quality materials such as stainless steel or aluminized steel. These materials offer resistance to corrosion and ensure long-term durability, especially in harsh environments.

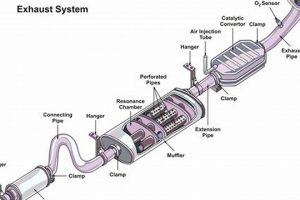

Tip 4: Examine Muffler Construction Type: Baffled components utilize internal chambers to cancel out sound waves. Packed mufflers use sound-absorbing material, like fiberglass. Chambered designs are generally more durable and offer consistent performance over time, while packed mufflers may require eventual repacking.

Tip 5: Research Reputable Manufacturers: Select a component from a well-known and reputable manufacturer with a proven track record of producing high-quality exhaust systems. Research customer reviews and ratings to gauge product performance and reliability.

Tip 6: Address Drone Mitigation: Drone, a low-frequency resonance, can be particularly noticeable in modified diesel engines. Look for components specifically designed to mitigate drone, such as those incorporating resonators or Helmholtz chambers.

Tip 7: Check Compatibility with Existing Modifications: Ensure the selected component is compatible with any other modifications made to the exhaust system or engine, such as aftermarket downpipes or exhaust manifolds.

Selecting an appropriate exhaust component for a modified 6.7 Cummins involves a careful balance of sound control, performance optimization, and durability considerations. By following these guidelines, owners can make an informed decision and achieve the desired results.

The next section will provide insight in proper installation and maintenance to maximizing the life of the new exhaust part.

1. Sound Attenuation Effectiveness

Sound attenuation effectiveness is a critical characteristic when selecting an exhaust component for a 6.7 Cummins engine with removed emissions equipment. Deleting factory emissions control systems often results in significantly increased exhaust noise. Therefore, the capacity of an exhaust component to reduce this noise to acceptable levels becomes paramount.

- Muffler Design and Noise Cancellation

The internal design of an exhaust component directly impacts its ability to attenuate sound. Baffled designs, packed mufflers (fiberglass or steel wool), and chambered systems employ different strategies to cancel out sound waves. A straight-through design will offer minimal attenuation. A complex chambered design with tuned resonators may provide a noticeable reduction in decibel levels. The selected design must effectively address the specific frequencies generated by the modified engine.

- Decibel Reduction and Regulatory Compliance

The amount of noise reduction provided by an exhaust component is quantified in decibels (dB). Local noise ordinances often specify maximum permissible sound levels for vehicles. Selection should be based on the ability to reduce exhaust noise to comply with these regulations, avoiding potential legal repercussions. Documentation from the manufacturer should specify dB ratings.

- Subjective Sound Quality

Beyond simply reducing the overall noise level, the quality of the sound is a significant factor. Some exhaust components may effectively lower the dB level but produce an unpleasant tone or drone. The ideal product will reduce noise while maintaining a desirable exhaust note that is not abrasive or fatiguing, especially during extended driving.

- Material Composition and Resonance

The material from which the exhaust component is constructed impacts its ability to absorb or dampen vibrations that contribute to noise. Thicker gauge materials and specific alloys can minimize resonance and reduce the propagation of sound waves. A higher quality material dampens vibration for a quieter experience.

These facets underscore the integral role sound attenuation effectiveness plays in selecting the ideal exhaust component for a modified 6.7 Cummins. A proper choice balances performance considerations with the need to manage exhaust noise, ensuring both legal compliance and a comfortable driving experience. The goal is to mitigate unwanted noise while retaining a pleasing engine sound.

2. Exhaust Flow Optimization

Exhaust flow optimization is intrinsically linked to selecting the most suitable exhaust component for a 6.7 Cummins engine following the removal of emissions control systems. The capacity of an exhaust system to efficiently expel exhaust gases significantly influences engine performance. Therefore, an appropriate exhaust component must minimize restrictions to maximize engine output.

- Backpressure Reduction

Backpressure, the resistance to exhaust gas flow, directly impacts engine efficiency. Excessive backpressure hinders the expulsion of spent gases from the cylinders, reducing power output and increasing fuel consumption. A well-designed exhaust component minimizes backpressure by providing a less restrictive pathway for exhaust gases. The selection of an exhaust component with a larger diameter or a less restrictive internal design can substantially improve exhaust flow and engine performance. Aftermarket exhaust components often advertise a percentage reduction in backpressure compared to the factory system.

- Turbocharger Spool-Up

Enhanced exhaust flow contributes to improved turbocharger response. A less restrictive exhaust system allows exhaust gases to reach the turbocharger more quickly and efficiently, resulting in faster spool-up and reduced turbo lag. This translates into improved throttle response and increased low-end torque, enhancing overall drivability. Certain exhaust designs are explicitly engineered to optimize turbocharger performance by minimizing exhaust restrictions near the turbocharger outlet.

- Exhaust Gas Temperature (EGT) Management

Efficient exhaust flow helps to reduce exhaust gas temperatures. By facilitating the rapid removal of hot exhaust gases, an optimized exhaust system prevents heat from building up within the engine. Lower EGTs contribute to improved engine reliability and reduce the risk of overheating, particularly under heavy load or during prolonged high-performance operation. The proper exhaust part design will remove heat more quickly, cooling the engine for more efficient operation.

- Engine Horsepower and Torque

Ultimately, optimized exhaust flow translates into increased horsepower and torque. By reducing backpressure and improving turbocharger response, a less restrictive exhaust system allows the engine to breathe more efficiently. This results in a noticeable increase in power output across the engine’s operating range. Dyno testing before and after an exhaust system upgrade can validate improvements in horsepower and torque, quantifying the benefits of exhaust flow optimization.

These factors illustrate the critical role exhaust flow optimization plays in the selection of the most effective exhaust component for a modified 6.7 Cummins engine. By carefully considering these aspects, owners can choose a product that not only manages sound but also enhances engine performance and reliability. The aim is to realize the full performance potential of the modified engine.

3. Material Longevity & Durability

Material longevity and durability are foundational elements in determining the optimal exhaust component for a modified 6.7 Cummins engine, particularly when factory emissions equipment has been removed. The harsh operating conditions inherent in diesel engines, characterized by high temperatures, corrosive exhaust gases, and exposure to road debris and environmental elements, necessitate the use of robust materials capable of withstanding prolonged stress. Premature failure of an exhaust component due to inadequate material properties can lead to increased noise levels, reduced performance, and ultimately, costly repairs or replacements. For example, the constant thermal cycling experienced by the exhaust system of a heavy-duty truck pulling heavy loads exposes weaknesses in inferior materials.

The selection of materials like T304 stainless steel, known for its high chromium and nickel content, directly correlates with the extended service life of an exhaust component. This alloy exhibits exceptional resistance to corrosion and oxidation, crucial factors in preventing rust and deterioration over time. Aluminized steel, while offering a more economical alternative, provides a protective coating that delays, but does not eliminate, the onset of corrosion. The gauge, or thickness, of the material also plays a significant role; thicker gauges provide enhanced structural integrity and resistance to physical damage from impacts. A thin-walled exhaust component is more vulnerable to damage from road hazards. The selection and durability of the materials are key factors in the exhaust components ability to last.

In summary, the material composition and build quality of an exhaust component designed for a modified 6.7 Cummins engine are not merely aesthetic considerations but integral determinants of its long-term performance and reliability. The financial implications of selecting substandard materials extend beyond the initial purchase price, encompassing potential downtime, repair expenses, and the inconvenience associated with frequent replacements. Therefore, prioritizing material longevity and durability is essential for achieving a cost-effective and dependable exhaust solution.

4. Drone Frequency Reduction

The connection between drone frequency reduction and the selection of an optimal exhaust component for a modified 6.7 Cummins engine is significant. Drone, characterized by low-frequency, resonant sound waves, is particularly pronounced in diesel engines after emissions control systems are removed. This phenomenon results from the altered exhaust dynamics, creating a resonant frequency within the exhaust system itself. An exhaust component designed for drone frequency reduction is essential to mitigate this undesirable characteristic, enhancing the driver experience and overall vehicle comfort. A failure to address drone can lead to driver fatigue and passenger discomfort, especially on long journeys. For example, an aftermarket exhaust system that significantly increases power but produces an unbearable drone at highway speeds would be considered less than optimal, despite its performance gains.

Effective drone frequency reduction is achieved through various exhaust component design strategies. These include the incorporation of resonators, Helmholtz chambers, and specifically tuned baffling systems. Resonators are designed to cancel out specific frequencies by creating an out-of-phase sound wave. Helmholtz chambers, acting as acoustic filters, attenuate targeted frequencies. Baffling systems, when carefully engineered, can disrupt the formation of resonant frequencies. The selection of the appropriate design depends on the specific frequency range of the drone produced by the modified engine. Some exhaust manufacturers provide frequency analysis data to aid in the selection of components best suited to address particular drone characteristics. For instance, an exhaust component incorporating a Helmholtz chamber tuned to 120 Hz might be specifically effective in reducing a common drone frequency in a modified 6.7 Cummins.

In conclusion, drone frequency reduction is a crucial consideration when selecting an exhaust component for a 6.7 Cummins engine with removed emissions controls. The presence of drone can significantly detract from the driving experience. By prioritizing drone mitigation through the selection of appropriately designed exhaust components, owners can achieve a balance of performance enhancement and comfort. Overlooking this aspect can result in an exhaust system that, while potentially increasing power, introduces unacceptable levels of noise and vibration.

5. Compatibility with Modifications

The selection of an exhaust component for a modified 6.7 Cummins engine necessitates a thorough assessment of its compatibility with existing aftermarket modifications. The removal of factory emissions equipment often initiates a cascade of subsequent upgrades intended to optimize performance. The exhaust component must seamlessly integrate with these modifications to realize their full potential. For instance, the installation of an aftermarket turbocharger, a common modification, can significantly alter exhaust gas flow and backpressure characteristics. Therefore, the selected exhaust component should be appropriately sized and designed to accommodate the increased flow rate without creating undue restriction, a condition that would negate the benefits of the enhanced turbocharger.

Ignoring compatibility can manifest in various adverse outcomes. A mismatch between the exhaust component and other modifications may result in suboptimal performance, including reduced horsepower, diminished fuel economy, and elevated exhaust gas temperatures. Compatibility issues can extend beyond performance, impacting physical fitment and installation. An exhaust component designed for a stock configuration may require extensive modification or even be entirely incompatible with a vehicle equipped with a lifted suspension or relocated fuel tank. Such scenarios lead to increased installation costs and potential compromises in the vehicle’s structural integrity. Examples of this include components that interfere with relocated fuel tanks, modified suspensions, or aftermarket bumpers.

In summary, compatibility with modifications is an indispensable criterion in the selection process. It ensures that the exhaust component performs as intended and harmonizes with the overall performance goals of the modified engine. Addressing compatibility issues proactively mitigates the risk of suboptimal performance, fitment challenges, and potential damage to other vehicle components. By considering the existing modifications, owners are better equipped to select an exhaust component that optimizes the performance and reliability of their 6.7 Cummins engine.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust component selection for 6.7 Cummins engines with deleted emissions systems. The information provided is intended to offer clarity and guidance for informed decision-making.

Question 1: What constitutes the “best muffler” for a deleted 6.7 Cummins?

The optimal exhaust component is one that effectively balances sound attenuation, exhaust flow optimization, durability, drone frequency reduction, and compatibility with existing vehicle modifications. A singular “best” option does not exist, as the ideal choice is highly dependent on individual needs and priorities.

Question 2: Why is choosing the correct exhaust component so important after deleting emissions equipment?

The removal of factory emissions systems significantly alters exhaust characteristics, often increasing noise levels and changing backpressure dynamics. Selecting an inappropriate exhaust component can lead to excessive noise, reduced performance, or even engine damage. Proper selection is crucial for maintaining drivability and preventing detrimental effects.

Question 3: Can an aftermarket exhaust component improve engine performance?

Yes, a properly selected component can improve engine performance by reducing backpressure and optimizing exhaust flow. This can lead to increased horsepower, improved torque, and better fuel economy. However, it’s imperative to choose a component that matches the engine’s performance profile and intended use.

Question 4: What materials are most suitable for exhaust components on a modified 6.7 Cummins?

Stainless steel (particularly T304) offers superior corrosion resistance and durability. Aluminized steel provides a more cost-effective alternative but is less resistant to corrosion. Material thickness (gauge) is also important; thicker materials are more resistant to physical damage.

Question 5: How is drone mitigated in an exhaust system for a modified 6.7 Cummins?

Drone frequency reduction is achieved through specific exhaust component designs. Common methods include the incorporation of resonators, Helmholtz chambers, and carefully tuned baffling systems, which selectively cancel out or dampen targeted frequencies.

Question 6: What compatibility issues should be considered when selecting an exhaust component for a modified 6.7 Cummins?

The component must be compatible with all other aftermarket modifications, such as turbochargers, downpipes, and suspension lifts. Physical fitment issues, as well as potential interference with other components, must be carefully assessed before making a selection.

Choosing the right exhaust part requires a holistic evaluation of performance characteristics, noise reduction capabilities, build material, and proper fitment to other modifications. Consulting with experienced mechanics can clarify any remaining issues.

The following section of this article explores the common brands or vendors selling a “best muffler for deleted 6.7 cummins”.

Conclusion

The selection of the most suitable exhaust component for a modified 6.7 Cummins engine, where emissions control systems have been removed, is a complex process requiring careful consideration. Performance characteristics, sound attenuation, material durability, drone frequency mitigation, and compatibility with existing modifications must all be weighed to achieve an optimal balance. A singular solution does not exist, and the ideal choice is highly contingent on specific vehicle applications and owner preferences.

Proper exhaust system selection for modified diesel engines is a critical element in maximizing performance and maintaining driver comfort. Continued advancements in exhaust technology will likely offer improved methods for managing both sound and backpressure. Careful product evaluation and consultation with experienced professionals remain the most effective approaches for achieving satisfactory results in modified diesel exhaust systems.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)